Chasing records is no easy thing to do or even consider. When you factor in how much more corner speed and straight away speed you have to reach, it becomes very evident that safety needs to be addressed as well. So with that being said, I sent Sheri, my time attack prepped Honda S2000, to Touge Factory in Wheeling, Illinois to add side impact protection, forward roll over protection, and to tie the cage into the front shock towers.

Unfortunately, my old roll bar was not suitable to built off of. The main hoop was deemed good to use but the bars that ran down to the rear shock towers were not. Also, the plates where they were welded to were deemed unsafe, so they had to cut them out, an expensive mistake that I have learned from.

The old bar didn’t actually go to the shock tower, so I wanted Touge Factory to make sure that the new bars did. They also reinforced both shock towers top and bottom to make sure that it’s sturdy and provides the maximum amount of support possible.

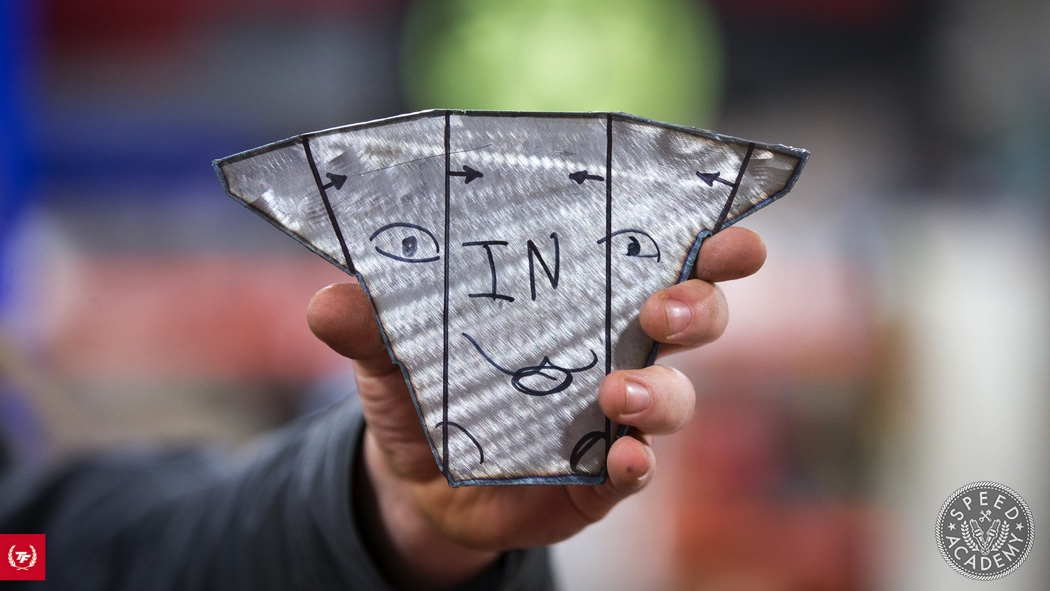

The new design also put the rear bars much further apart from each other. You can see where the old bars went in the photo above.

Instead of the traditional floor boxes that are welded to the bottom of the floor, TF opted to put the boxes on the side where it was far more rigid and would take more force in case of a rollover. It also gave me more leg room in case of a collision. It’s also more leg room to get my fluffy self in and out of the car.

It may look simple to build a sill-mounted box like this, but here are a few steps in the process to give you a better appreciation for the craftsmanship involved.

Instead of my janky custom made seat bracket, I opted for TF to make me a new one since I was getting a new seat anyway. I wanted something that sits as low as possible but was not going to break on me. A simple solution was formed, welding some thick steel flat stock together and connecting the side rails to that.

I chose a Sparco Circuit II seat because it’s fluffy-guy friendly (I’m a 36 waist) and affordable for an FIA spec halo seat. I was originally looking at a Racetech 4119, but that was not reachable for me price-wise.

The bar that stretches over me has a slight kink in it to stay tight against the hardtop and give me maximum helmet clearance. It fits like a glove with the hardtop on.

The hole in the firewall where one of my harnesses goes is a perfect hole to send the bar for the shock tower through. On both sides at that! Saved a lot of time (and money) by being able to do this. It’s almost like Honda knew I was going to need a cage.

TF also added gussets to tie the roll cage into the window seal. They add rigidity and they do look cool in my opinion.

Door bars protrude into the door, so the doors were gutted. TF did that because I’m a fluffy guy and need all the room I can get to get in and out of Sheri. Not to mention that it gives a buffer from myself and the cage coming in contact with my feeble bones.

I’m very pleased with how the cage work turned out. It was finished in a timely manner and at a reasonable price. If you are looking at fab work in the Chicago area and you want it done correctly the first time, be sure to contact Touge Factory (http://www.tf-works.com/). And if you love cool fabrication photography, be sure to check out TF’s Flickr thread because it’s full of fantastic photography and really shows off their in-house fabrication skills.