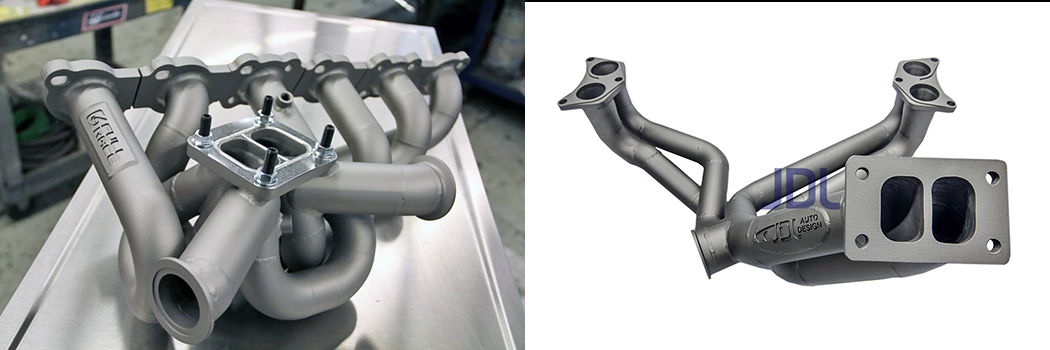

Designing a high-performance twin-scroll tubular manifold like those available from top quality manufacturers like JDL Auto Design and Full-Race is no simple task. Fitting equal length primaries into the tight confines of a turbocharged car’s engine bay while maintaining proper radius bends and strong exhaust gas flow characteristics is a serious design challenge. Determining the best length and diameter of the primaries and angle of the merge collector also requires a lot of R&D, as does choosing the best wall thickness and material for the tubing itself. As Geoff Raicer from Full-Race told me when I was originally researching this subject, “Because of the increased turbine efficiency found in twin-scroll systems, twin-scroll manifolds can often use a smaller runner than a single-scroll design. However, due to the complex shape of the runners and the requirement for a second wastegate and dumptube (one for each side of the divided turbine) there’s more mass and more parts that adds expense and complexity. Plus, twin-scroll turbos are physically larger than their singlescroll equivalents, so it’s more difficult to make them fit into already cramped engine bays.” Overcoming these challenges means developing extremely robust manifolds that make smart use of the available space, something that the best manufacturers including Full-Race does with the help of computer programs like SolidWorks and other proprietary processes.

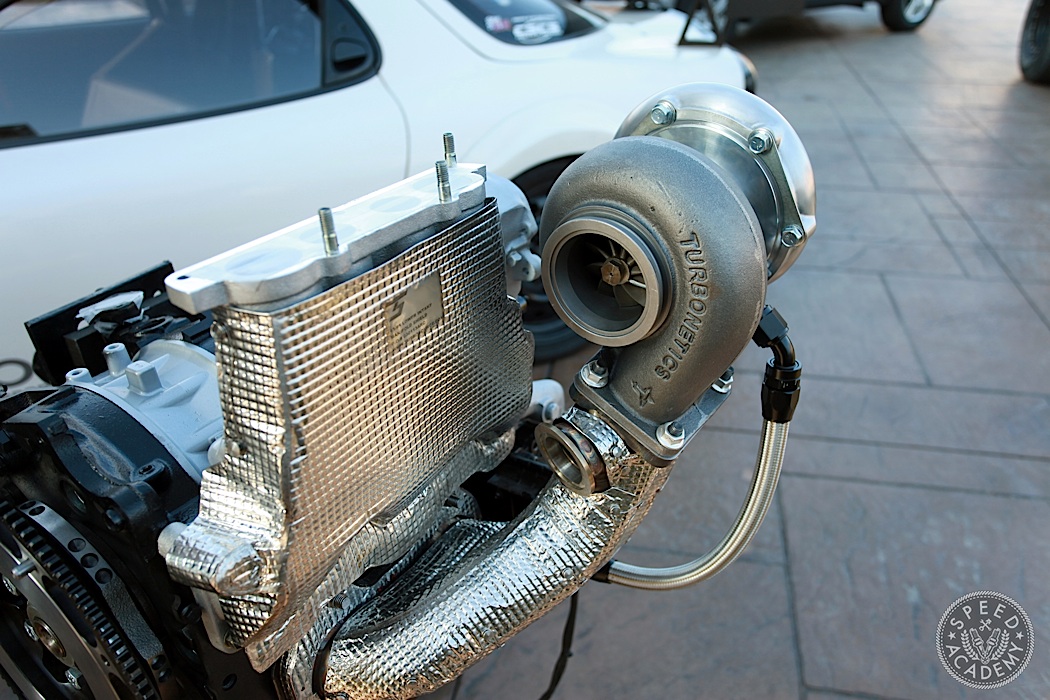

Our FD RX-7 project makes some tasty rotary jam thanks to its twin-scroll Turbonetics GTK-700 turbocharger and Full-Race exhaust manifold. We should have an Intro story on this car for you shortly!

All this hard work does translate to serious performance gains in the power delivery department, though, particularly at spool-up and peak torque where sophisticated tubular twin-scroll manifolds properly matched to a twin-scroll turbo deliver superior airflow to single-scroll or OE twin-scroll designs. According to Geoff, “Our twin-scroll turbo kits have a higher average cylinder pressure and turbine efficiency, while single-scroll systems tend to have a higher peak cylinder pressure and exhaust backpressure. We have found the twin-scroll systems have higher backpressure at low RPM (which is good for turbo spool-up) and lower backpressure at high RPM (which is good for top end performance). On the other hand, single-scroll systems have lower backpressure at low RPM (bad for spool-up) and higher backpressure at high RPM (which hurts top end performance).” Keep in mind, though, that the manifold design and a/r ratio of the twin-scroll turbo are spot on for optimum performance, so if you’re unsure of how to properly match the manifold and turbo to your engine and designed power delivery, consult with an expert or buy a turnkey turbo kit from a reputable manufacturer.

It’s certainly possible to generate huge power and great high rpm performance with a single-scroll turbo system. There are plenty of examples of very high horsepower single-scroll turbocharged engines out there. Hell, we’ve seen a few 1,000-hp Supras with single-scroll snails under the hood. And although switching from single-scroll to twin-scroll can be expensive, for hardcore boost junkies who want faster throttle response without giving up any top end, there is no better solution than a twin-scroll setup. With the added benefits of higher TC efficiency, lower cylinder temps and EGT’s which allow more aggressive timing and fuel mapping, and the freedom to run valve overlap, twin-scroll turbo system design is really a perfect match for the high specific output and higher compression ratio engines featured in many of our favourite high-performance machines these days.