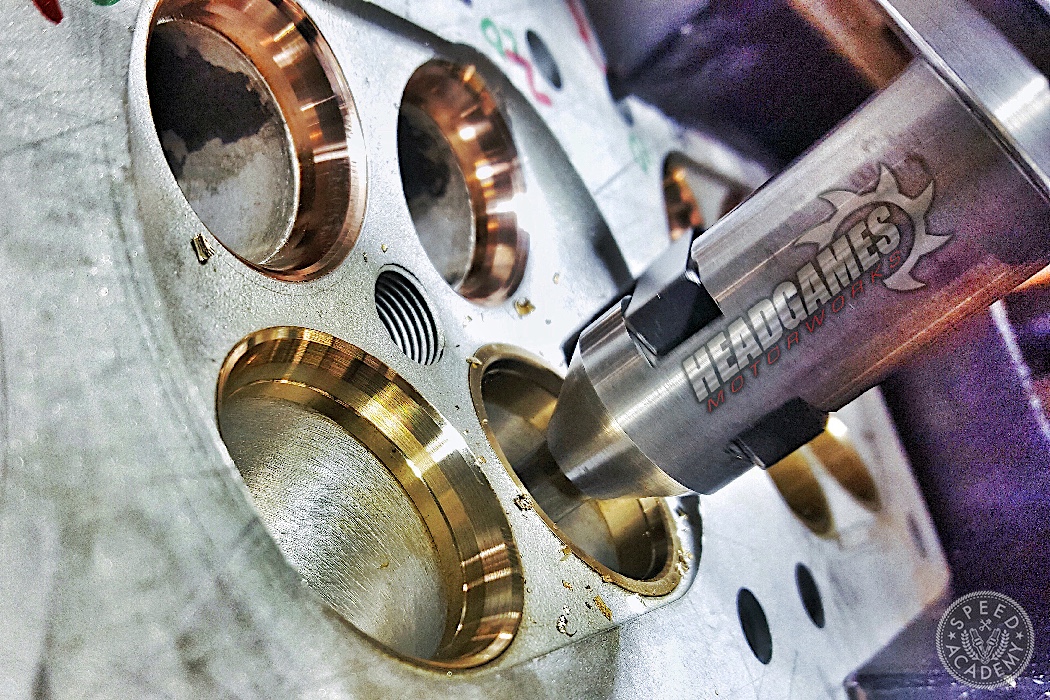

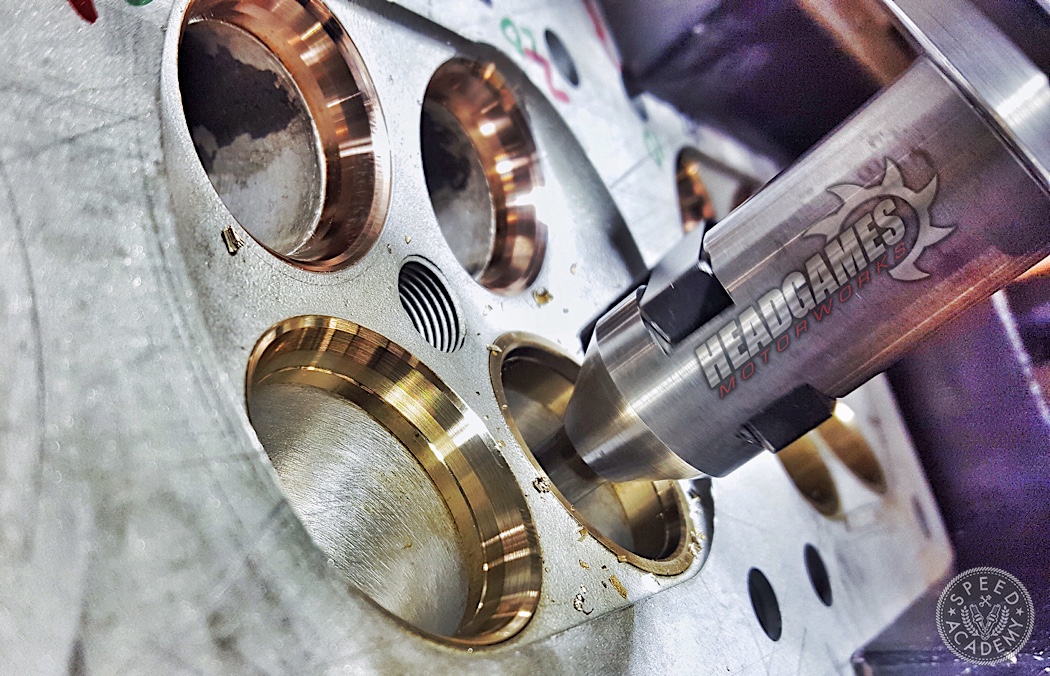

About the Author: Dave Localio is a long-time friend of ours and the owner/operator of Headgames Motorworks, a cylinder head specialist founded in New Jersey in 2001. Dave and his team have amassed a huge amount of experience and expertise and are now creating some of the best performing cylinder head and cam packages for both domestic and import vehicles, be it for street/strip use or full blown race applications.

Myth #1. CNC is “better”

This one depends on the piece in the machine. If your making billet heads, the accuracy of the CNC is worth talking about, because you’re making something from scratch and making a batch of them ensures that they will all be the same. But when it comes to CNC machining a factory cast cylinder head, talking about the accuracy of the machine is a moot point. I say this because the factory head is cast, which means there will be some variation from head to head because of the imperfections that come from the casting process. That’s where the words “core shift” comes into play, because when we get cast heads back from the CNC shops there is not one that is exactly the same. In fact, in the head there is no ports that are the same. You can even see where the CNC did not touch the casting in one port but did in the others. That’s because the CNC machine does not know where the ports are, just where they are supposed to be. Meanwhile, a hand knows the center of that port every time. So, what does this mean?

While a CNC is better than a hand at many things, when it comes to porting your factory cast cylinder head it is really just faster, meaning it’s faster than any human could grind and sand your head. So, instead of waiting weeks or months to get it back from the machine shop, someone with a CNC could rip through it in a few hours and have it on the floor ready for machine work. Talking about consistency machining an inconsistent part makes no sense except to market it as the best option. However, because there are cylinder head guys out there who do such a poor job hand porting, seemingly haven taken lessons from a blind person with a hammer and a chisel, they help perpetuate the myth that CNC porting is more accurate or “better”.

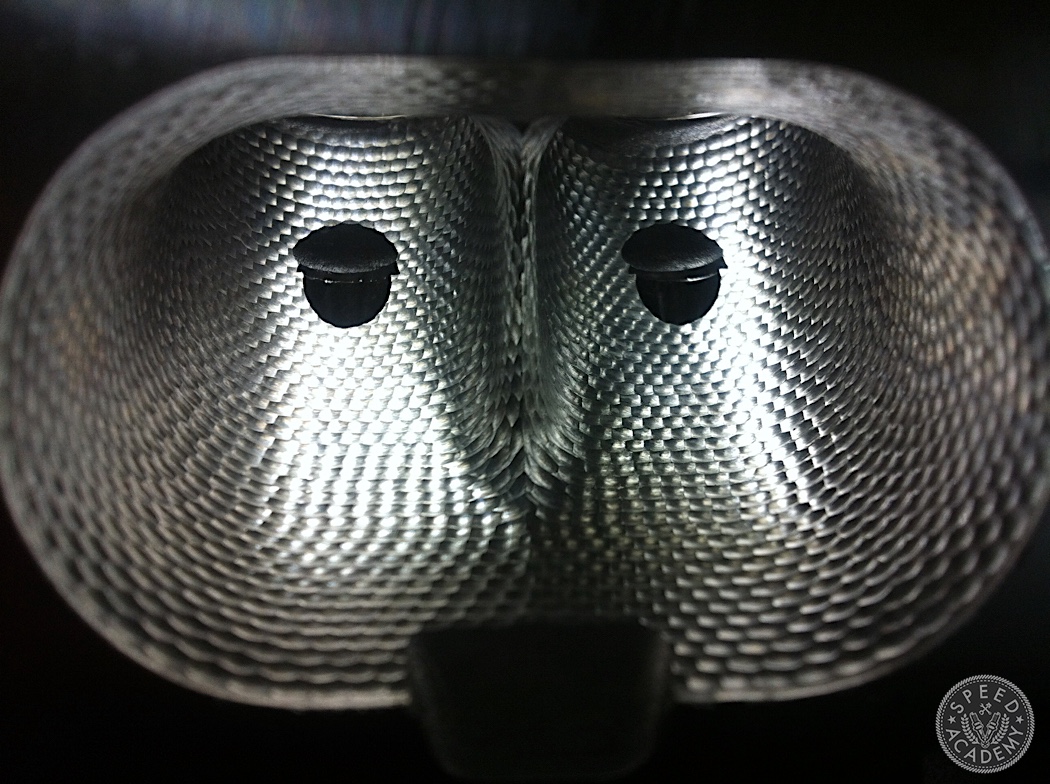

Myth #2. Dimple Ports

While we are on the subject, we should touch on dimple ports. The argument is that it works on golf balls because it creates a boundary layer of air and helps it move the ball faster and farther. In a port, we are looking to create a situation where fuel stays off the wall of the port. So the dimples would (in theory) help create this boundary layer of air that would keep the fuel off the wall and in suspense and atomized.

First off, more than likely you have an engine with modern fuel injection if your reading this. Modern fuel injectors do an excellent job of atomizing the fuel, especially with todays engines where injector location is engineered very carefully for optimized delivery. So, the only true advantage I see in dimple ports is if you’re playing discus with the cylinder head and want to see how much farther you can throw it. If there was any real basis for dimple ports, you’d be seeing it in high-performance factory engines and professional level race engines and that’s simply not the case.

Myth #3. Mirror Polishing

Charlie Kulp taught me how to grind. The man was working with Smokey Yunick back in the 1960s (look that name up on Google if you’re unfamiliar with Smokey, he’s a racing legend and innovator on a level few others could touch) and when they ran stuff in NASCAR they tried mirror polishing on the heads. It didn’t work then and it won’t work now. The reason being is that when you make the walls of the port too smooth, the air moves so fast and sticks to the walls of the port such that the fuel falls out of suspension, causing inconsistent fuel delivery to the combustion chamber.

Myth #4. Bigger is Better

It’s super easy to make a port as big as it can be. And we all know if it were easy, everyone would be doing it. But, that is kinda the problem. There are more places that believe in this theory than not. So, what you get is an industry full of heads that flow great from .500 lift on but are lazy on the car. Because velocity means more than flow! Air flow means something, and big ports and big valves don’t equal air speed. Simply put, the big stuff shines on the flow bench but runs like a dog with flees on the car.

Myth #5. Because It’s Ported, It’s Good For My Application

Here is a gigantic misconception. With the advent of CNC you have a lot of performance shops and even CNC shops selling heads and selling them in one configuration. All of the them are ported to the max, with an oversize valve and flow insane numbers at max lift. But here’s the problem, your making 700 and want more power. You street drive the car a few hundred miles a month. You love beating on it. Put the big head on it and it losses all torque and has a dyno ramp that looks like a ski slope. That’s because the head is too big for your application. This is especially true with turbo cars. The max effort head will make the car lazy into boost. It will only make more peak power. That’s why asking for a flow sheet is so irrelevant. The dyno mimics the flow sheet in this case. It will make more jam, but where it makes the jam is what you should be concerned with.

Myth #6. Flow Testing

The biggest question we get daily,”What does it flow?” yet this is absolutely the most misunderstood part of cylinder head purchasing. And kind of where the bigger is better theory makes cylinder head sales. As stated above, you have a bunch of humans that don’t understand flow testing throwing everything at the head for the mighty CFM number at max lift and forget that it only hits this point once where they should be concentrating their efforts on everything that happens in between. The valve goes up and down through the lift ranges twice. The way the head behaves on the bench is indicative of how it will behave on the car most of the time. Why do I say most? There has been heads we have done that flow like a gangster at a rap party but run like a fat man chasing a banana. You can’t always believe the flow bench because there are so many different variables going on in the engine that the bench cannot capture or account for. Things like overlap, lift and duration of the camshaft can play a role. Asking “what does it flow” doesn’t necessarily help you make the right decision and often times it adds confusion for the novice buyer.

Myth #7. The Gasket Match

This myth started on the domestic side of things. With the old heads, people would open the intake or exhaust port to a particular gasket. This was supposed to be the end-all performance enhancement. Truth is, there is zero thought by gasket manufactures on how big your port is supposed to be. The job of the gasket is to seal, not to enhance flow. When we look at this myth’s origins, people where trying to open up the cylinder head at its pinch point which would be the push rod restriction. Sport compact heads don’t have this restriction. And, the truth is most heads do not need a gasket match for the performance level they’re at. Here at HeadGames we do not usually open anything near the gasket til 1500-whp on 6-cylinder cars and 1200ish on a 4-cylinders. It’s better described as a port match and not a gasket match. Port match means that the port size most ideal for the port shape, NOT the gasket.

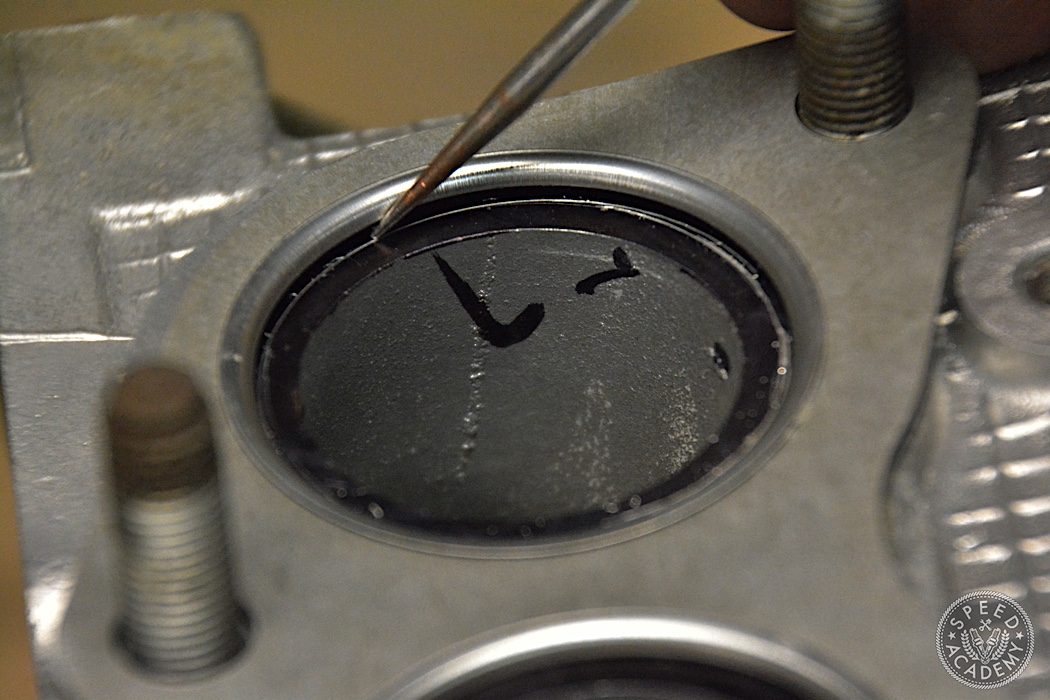

Another question we get daily around here, “Do you do a radius valve job?” or “Do you do a 5 angle valve job?”. A valve job is not just a valve job. You can’t just throw any 5 angles or any angles at a head and expect results. Typically a valve job consists of 3 angles from the factory. Almost any cylinder head on every car since the 1960s has a 45-degree “seat” angle (with the exception of muscle Pontiac and Oldsmobile that had a 30-degree seat angle). We say seat angle, because this is the angle which the valve sits on when it is closed. Then there is a top and a bottom cut. When we add angles, they are added to the bottom of the 45. An example of a 3 angle would be 35-45-60 angles. When we increase the number of angles, we would say 35-45-60-70-90 for a 5 angle. Now, that we have the number of angles, the only way to really know what angles actually like to be on the head, we have to use the flow bench, dyno and on-track testing. We do extensive, labor intensive testing on every head for valve jobs. Not any valve job work just because it has a number of angles. They have to be the right angles for that particular cylinder head.

Also, radius valve jobs are a popular question. Do they work? Sometimes. Do they work on everything? NO. The radius looks great, and feel it up with a finger and you might think this is the most awesome invention since sliced bread. But on the flow bench and on the car it can be a heart breaker. There is more instances than not where a full radius valve job will hurt more than help. This is especially true on an intake seat. Air doesn’t like to turn. It likes straight paths. And it loves angles. But not too many, because too many angles on a small seat can make it a radius.

Myth #9. Big Valves

Tied to the subject of valve jobs, larger valves are certainly a big part of why people use them. Here is the deal. In the multi valve community, there are many places that do an oversized valve simply because they do not have valve job technology. But if you don’t have valve job technology, then you probably don’t know where to put the throat diameter. The area under the valve seat has more potential for flow than almost anywhere else in the head! It also has the biggest potential to hurt flow by being too small or too big!

Port shape is the second biggest advantage when it comes to a ported head. When we port heads by hand, a lot of people ask, how do you know when to stop? Well, the answer is in the port shape. Once the shape is mapped out then you just make everyone the same. But, this is where the flow bench can be your friend or your heart breaker, depending on what transpires. It’s almost impossible to decipher this unless you have owned a flow bench or see enough ports to know what shapes change flow characteristics on particular cylinder heads.

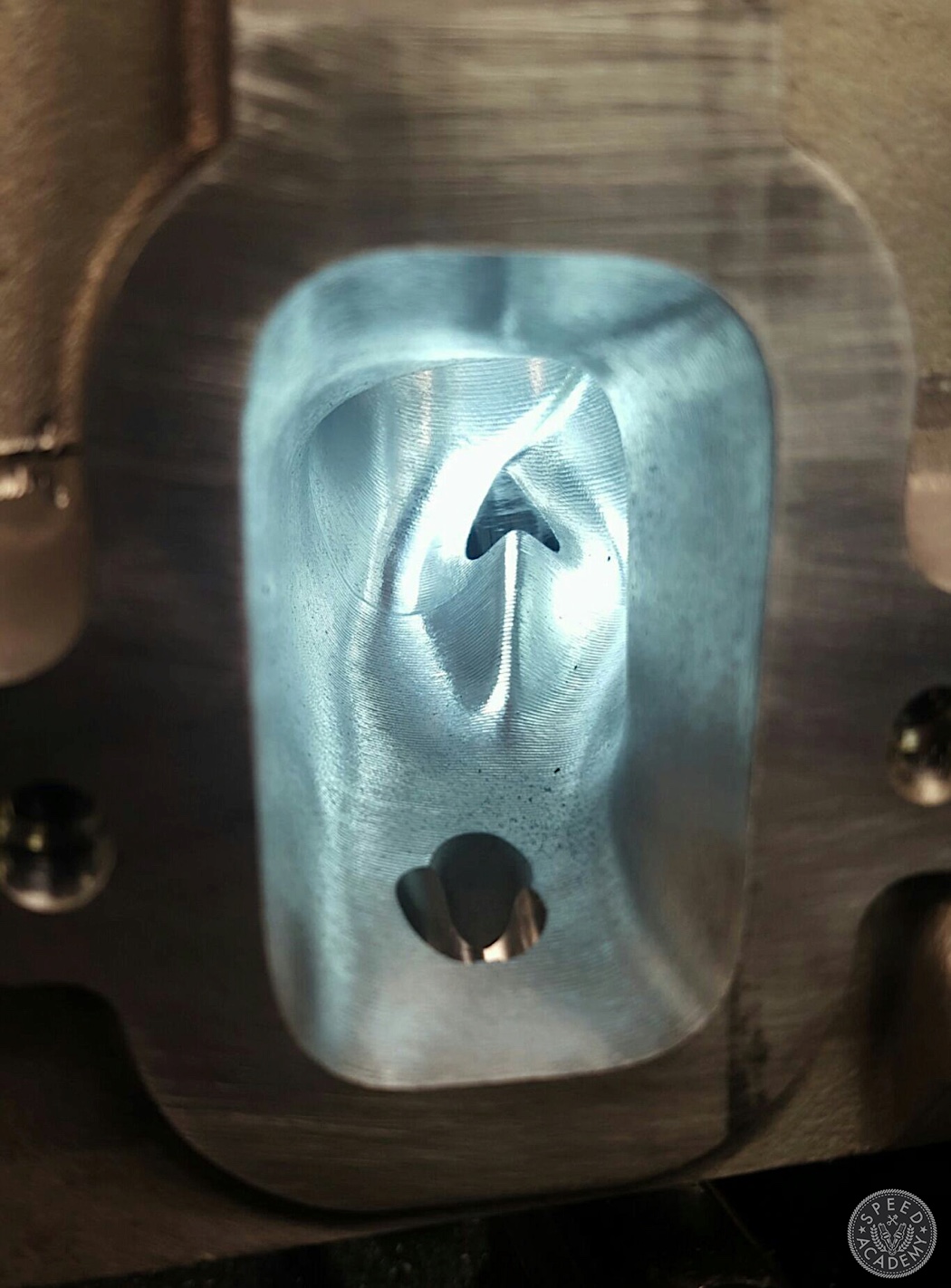

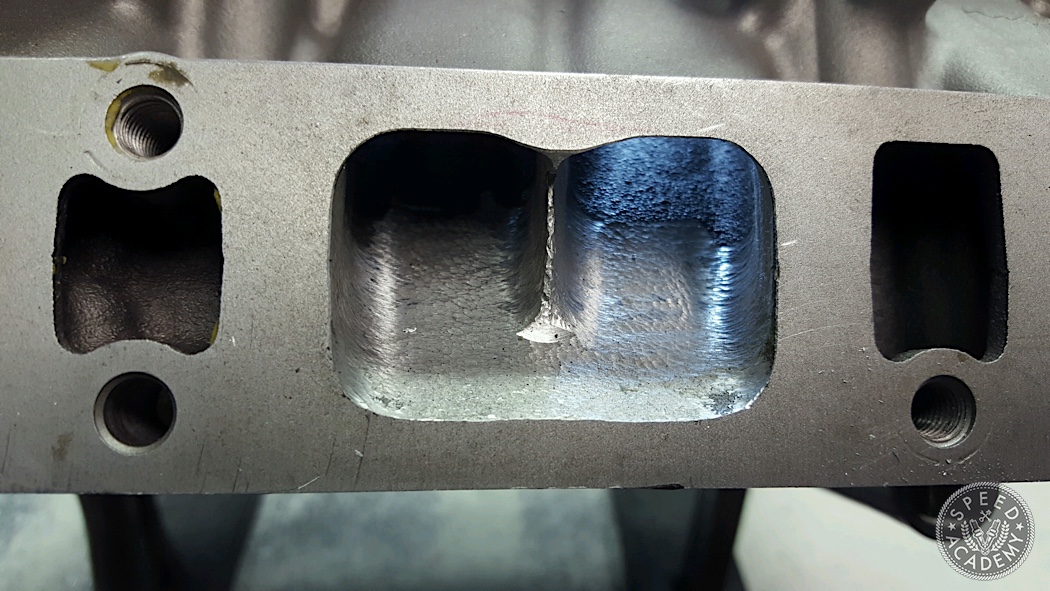

Best way to show this is by an example we had in our development in the 4-cylinder Mustang Ecoboost head.

When we first looked at this head, it was easy to see how Ford completely separates the two intake ports. No sport compact head does this so far out into the port. The port is very long and small. Seeing other heads on the market, most are knocked back the center of the 2 ports and made it appear to be a larger runner. It looks awesome!

So, we did one port to see what it does on the bench and only did that section of the port to see how it behaved. WELL…it didn’t behave well at all. In fact, it lost 40 cfm almost everywhere. Thinking maybe it was the way we shaped it vs the competition, we mimicked their port entrance for the second testing. Same results. It was obvious no one had actually tested this on the flow bench until now.

So if we were losing so much airflow, where was it going? Well, when you don’t know you ask someone smarter. We hit up our friends at McLaren, Dan Archer and Tim “the airflow doctor” Connelly. We went through the port and by using velocity probes learned that the air flow had actually moved to a corner of one port side because of the divider! It looked cool, but didn’t work.

We went back to the drawing board and kept the divider. Ported and just changed the shape of the intake port. 90 cfm gain! And this head went on to set the national ET record.

Entertaining read. But not that convincing if you ask me. On one hand you should not dimple because modern fuel injected cars atomise the fuel really well and don’t need it. And if it worked you would see racing engines use it. But then you should not polish, because in the sixties it did not work. Radius valves dont work because air “likes” sharp angles followed by straights. My question then is, why do we not form the port with sharp angles instead of a smooth curve? Why do we see polished ports and radius valves on formula one engines?… Read more »

Hello Simon. In your response to the sharp angles, a smooth curve on a port runner is much different that the valve seat area. There is less real estate/time to work with on the valve seat area than the runner. Smooth turns are always considered first. Because there’s not a lot of material to work around the short turn, a gradual curve isn’t going to work, but a sharp angle will jerk the air in the direction you need it to go in short work. However, it’s like playing Russian roulette – you can’t do too many sharp angles or… Read more »

Show me some F1 engines with polished ports.

Can we compare standard street engines which cuts around 7K to F1 engines which begins from 7K when we are talking about porting and so on?

Really good read here. I’m new to the whole porting world and it’s a lot to take in. I have not done any heads yet because it seems overwhelming with how intricate they are and how much thought is put in to even the simplest port jobs. I have done a couple manifolds and “plenums” but they are so much simpler in my opinion. Any advice on someone completely new to porting heads? I’m going to practice on a head that I got from the junkyard. I just have a basic die grinder and standard Eastwood rolls.

How can this be a good read when you don’t know anything about porting?

Can we talk about how your tech is grinding with no eye protection and open toed shoes with metal chips everywhere?

Reelaax Dmoney, nothing to talk about. Some of us like doing machine work in flip flops during the summer and she’s dusting the port with a sanding roll not “grinding” on it.

“dusting” does not make it better.

a sanding roll still removes metal, and at a fairly high rate of speed.

get metal drilled out of an eye and it is a lesson to remember for a lifetime.

not to mention she’s using the tip of the ‘duster’, which is quite long and subject to breakage…..good way to lose an eye.

Yup learned that lesson the hard way too.

Think that’s just a pose

Having said that,i don;t worry to much about my hair,but i allways make sure my nails are polished before i set to!!

Do you know what Personal Protective Equipment is? You can’t even accept that there was a mistake in your article, at least learn from it.

somehow you peeps thinkj you should tell others choices they are free to make. if she doesnt want to wear ppe, deal with it.

oh man she’ll eventually deal with it…painfully

you have no idea just how painful it is not only having a shard of metal in your eye, but also getting it removed at the surgery…

Very cool write up/avertisement… I’ve never ported a thing, but have thought of it countless times in my quest for an extra pony or two – I’m even having my heads off in a week or so to get the gaskets done (Subaru, go figure! ) and I talked to the guy doing it about a port and polish and he said no way, cuz he didn’t want to have to put his own time and effort into it, even though I was offering some cash for the project. And that’s okay… Especially now that I see how many ways… Read more »

since you have such access to a flow bench, i’d like to see you back up your claims that dimpling doesn’t work with actual data.

it’s also confusing how you state flowbench numbers are virtually worthless without factoring in such things like cam and lift , but then refer to losing flow on the flowbench to discredit other mods without also taking such things into consideration.

“Lost 40 cfm everywhere” meaning it lost flow at ALL LIFT POINTS. It lost it at .050, .100, .200, .350… You only prove…”You don’t know.”

Dimpling only works with solid objects with fluids/gases flowing around them. Such as wings and golf balls. It helps to keep the boundary layer stuck to the surface at the trailing edge or back end of the ball. This DECREASES drag by reducing turbulence; same reasoning to use vortex generators on aircraft wings to prevent layer separation. If it weren’t for the fact that the golf ball is round, dimpling by its self would slow it down.

Great read guys, everything I have found over the last 20 years you just covered. We now garannetee to beat any CNC’D OEM cast head especially in the mid 90’s stuff which we do a lot of in the sports compact stuff. Ive played which the dimples and got into the science behind it. This is what I have found… The biggest problem when people try comparing a golf ball to a port is. it’s at a lower air speed, so Re extension area isnt anywhere near our average port velocity. Also we have found there is a connection between… Read more »

With mpfi where the injectors are in the intake port. Seems to me a polish of everything prior to that point would be more beneficial than if you were to polish a carbureted system. There is no mention at all differences in characteristics of a carb (or throttle body) vs. port injection.

Don’t forget direct injection

Your grammar is terrible, get someone to proof read before you publish. At point 6 you say CFM is pointless, but by point 10 you’re using it to compare two heads? The whole article is badly written and doesn’t consider the bigger picture.

Nobody gives a fuck about your thoughts grammar Nazi. What we care about is making power and efficiency and separating the squirrels from the guys that knows what they’re doing. You’ll probably hate the way I respond to this but I don’t care.

Im no genius but I’m pretty sure Cnc machinist are aware of the inconsistencies in casting. I’m also pretty sure they use something called a probe to locate The center point. I’ve had the opportunity to see how that was done.

And you believe cnc’d heads are probed individually port by port? You do realize the whole benefit of cnc’d ports is speed and repetition right? What happens if the shift is .010 toward the roof? What if the shift is .020 to the floor? What if the port is dead nuts on except for the last .250″ to the right side of the SSR? Is there different gcode file for each instance ? lol

With regards to valve seat angles, there was no discussion of what happens in the real world with valve stem core shift and massive run out numbers. Basically manufactures of heads should sell with a warning, “Unless you check it yourself we can’t guarantee this cast head will work efficiently.” valve jobs with 3 or 5 or 15 angles mean little if run out is so great nothing seals.

So I recently had to go to a Ford escape with the 2 l EcoBoost for reasons I won’t mention here and I was trying to get some performance out of it without spending too much money or any money I’m a poor student right now and basically it has eight intake ports instead of four going into the two intake valves per cylinder it’s like a old Toyota RZ 4 cylinder except the ports are rectangular and there’s a big fat divider in between those just a flat surface but the intake manifold only has four ports so it’s… Read more »

I’m on the aviation side of things and find the article extremely important. I’ve never touched a cyl head for any reason. Air velocity is the Only thing that matters.

Definitely a professional lol. Flip flops in the shop, no safety glasses, or hearing protection. My aunt wouldn’t have even let her past the front desk like that.

Good reading.

Maybe off topic. But is it advisable to planning a cylinder head for higher compression to gain more power? I believe engine has 10 to 1 compression ratio!

Jaguar xj6 4.0 engine from 1996

Thanks!

I have 2 sets of Kawasaki DOHC ZX9R heads that Were mildly ported and cleaned up the valve bowls and than added larger valves . The head work great on the 13:1 C.R. engine with excellent power and torque through out the entire operating range When I started working on a couple other sets it dawned on me that the intakes needed to have the floors raised and the roof of the port heightened to straighten the runners to the valve bowls. The exhaust ports are horrible with a sharp downward bend in the port wall. Now I am asking… Read more »

What year is your Zx9? I have an 01

I enjoyed reading your post. The part about the EcoBoost engine is particularly entertaining knowing this head has been developed by Ricardo in UK, using state of the art simulation software nobody knows about, and it’s is probably very close to the ideal compromise for its application. One word about surface roughness: mostly everything you said is true, yet you cannot avoid a simple fact: the air molecules at the wall don’t move, and the air molecules in the middle of the duct (hopefully) do. This tells us there is a speed gradient where the air goes from whatever speed… Read more »

What can i put on the exhaust cause they port it too much it has a pipi hole

I have never read so many nasty comments by so many #DickInTheAss pronoun-men… Well… Not since they’ve been attacking Trump on Twitter and Facebook Anyway. Most readers would assumed the girl “without protective gear” is a model for your photos rather than some hairy guy with ear wax and a beer gut. These tough guy commenters aka make believe arm chair mechanics seem like they’re fighting to be the first to make the worst remark. This is a great write up and basics enough information to keep the Thomas The Tank Engine man-bun Millennial and his dress wearing son from… Read more »

Exactly I wonder how many people who post arbitrarily on websites (*Neo Gale Banks pugilists above), camera websites (*bitchy geeks who were bullied in HS), gun websites (frustrated hostile Nazis who never served), and the infamous political websites (rank ahole woke-Nazi feminine Libs), who really have any skin in the game? I wager not many. I found that the majority of those who post in the performance/hot rodding bogs, often repeat myths they heard, because it makes them sound knowledgeable. Spelling and syntax have little to do with experience and knowledge. I worked in a busy garage as a teen,… Read more »

There is so much wrong in this article and I don’t care how long you have been doing it I will put my results up against anyone else and we can test side by side. I have been competing in this for years and I am telling you that there is a lot of misleading information in this article. Bigger is not better – we will start with this one because it ignores a fact of desired RPM as well as cam selection. RPM and cubic inches are what determines how much runner you will need in CC. There is… Read more »

If you could write up a comprehensive article outlining basics to porting it would only help others. I have a set of Toyota 3URFE heads (W/supercharger) I want to port. It makes sense for my application. I can’t find a shop near me (Atlanta area) who will do the work. They only work on domestic GM, Ford, Mopar, etc. I’m faced with R&R and shipping them out to someone somewhere who may, or many not have necessary skills or experience. Thanks

I joined this discussion because I am wondering why are most people so angry at this article or how it is written, the author; whomever he might be has taken the time to share his point for view, for fucks sake just give him that and ignore what you don’t like! It’s not like it is going to change you life.

To the author, thanks for taking the time, I hope you read this and have a good day.