THE LAST STRAW

At my last track day, my car suddenly started misfiring hard. I wasted several sessions debugging, first discovering that it was the fuel pressure differential signal triggering the safety, but instead of disabling it I insisted on trying to figure it out. I finally gave up and turned it off. Later it turned out to be a loose connection. The circuits my dad built for me always function perfectly but he uses typical electronic hobbyist components so the connections were in screw terminals, and it rattled loose in a racecar.

I could have just retightened it, tossed some hot glue on it and kept going, but this was the straw that broke the camel’s back.

WHAT NEXT?

OK great, last straw… but then what? The only option that I was aware of which would not be a step backwards in some way was Motec, but there’s no way that was in the cards unless I started selling body parts. Then I saw some of the videos the Speed Academy guys did on AEM and I realized that could be the way to go for me.

I always knew that the Infinity 7 would offer me the control strategies and I/O I wanted, but the Motec dashboards were the only ones I was aware of that were sufficiently flexible in order for me to have the info I wanted. But the new AEM CD-5 and CD-7 dashes turned out to be just as capable, so I started looking into what else AEM offered and soon realized they offered everything I wanted and then some, with room to grow and it was a setup I could actually afford.

MORE BUT LESS

While the well polished and extensive functionality of the Infinity and CD-7 was very exciting, something that really excited me might be difficult to understand if you haven’t lived the alternative. It’s like buying a modern lithium cordless impact gun. If it’s the first tool you ever used to remove and install various fasteners, it’s just the tool you use, no big deal. But if you spend 20-years skinning and bruising your knuckles while twisting wrenches and ratchets, then you develop an unreasonable emotional investment in the power tool.

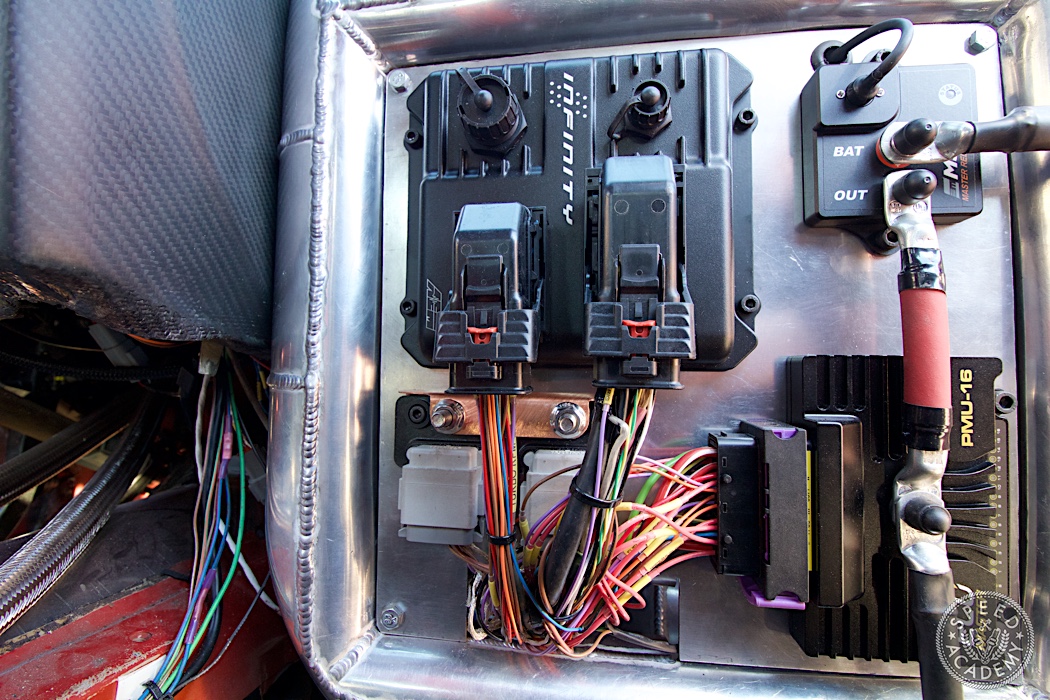

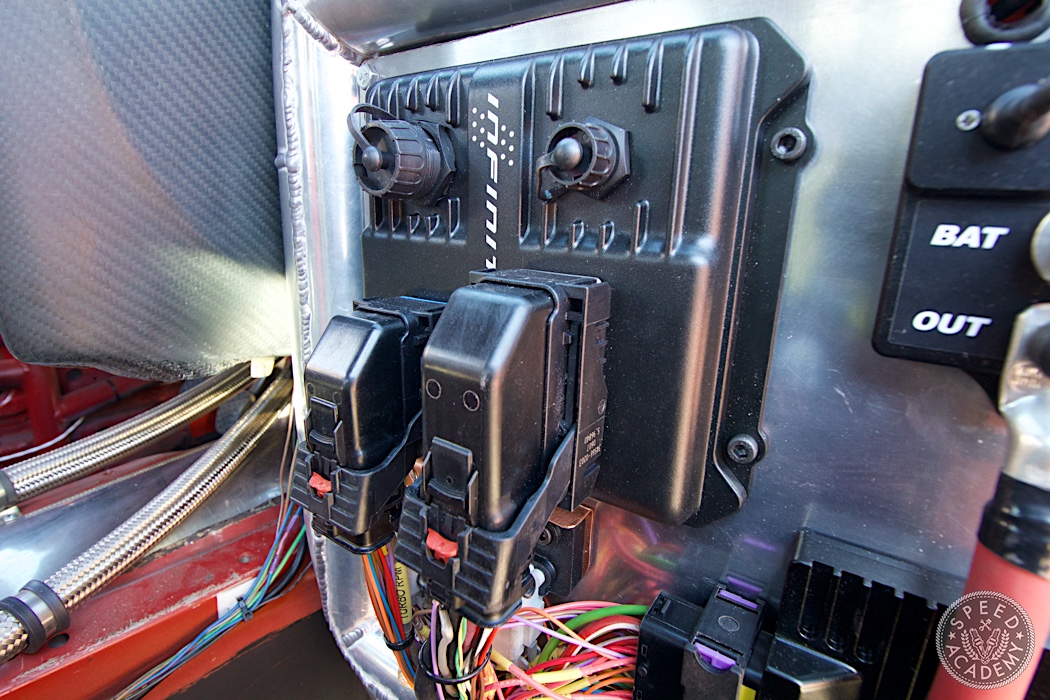

The same sort of thing was brewing as I realized how much simpler my car would become while becoming more functional, because everything was now going to be operated by the Infinity rather than my million ad-hoc boxes. On a balance sheet, it wouldn’t look like a big deal, but you have to have lived the years of wiring nightmare to appreciate this as much as I do. I wouldn’t even need my AIM Solo DL anymore because between the Infinity inputs and logged data, and CD-7 dash and VDM module providing track data, I would be one more module and cable down while having more comprehensive track logging than ever.

The same sort of thing was brewing as I realized how much simpler my car would become while becoming more functional, because everything was now going to be operated by the Infinity rather than my million ad-hoc boxes. On a balance sheet, it wouldn’t look like a big deal, but you have to have lived the years of wiring nightmare to appreciate this as much as I do. I wouldn’t even need my AIM Solo DL anymore because between the Infinity inputs and logged data, and CD-7 dash and VDM module providing track data, I would be one more module and cable down while having more comprehensive track logging than ever.

Some of the simplicity comes from some of what we’ve already talked about, stemming from the power of the ECU, allowing one unit to perform the functions that would normally take several boxes, which also require their own power and ground wires etc. Some of it also comes from advanced technology becoming prolific enough to be affordable to you and I, such as solid state relays replacing bulky fuseboxes (e.g. all the wires for a relay and fuse being replaced by an electronic component inside a digital box – the Infinity 7 has several of these).

DATA ICECREAM TRUCK

But one of the biggest revolutions in wiring simplicity while drastically increasing flexibility has been CAN bus. It’s a bit of a mystery to many people but for no good reason. The standard has a lot of fancy technical details to make it robust and flexible but as with everything, when you dig deep enough, it’s based on some simple ideas, understanding which usually gets you most of the way to understanding the complicated thing. In the case of CAN, or Controller Area Network, instead of having a wire for every signal, you put them all on one. Well, two for CAN but the idea is the same. The only question then is how do you get what you want out of it?

At first glance it seems like trying to separate the water of a specific river from a sea. But the CAN standard has a lot of cool rules that everything on the network obeys. The trick is that, rather than a sea, it’s more like an auditorium debate, where a bunch of people take turns speaking. There is no moderator telling them who is going to speak next, they’re all polite and when they start speaking together, they realize it and follow some rules to know who has to be quiet and wait.

What makes this idea extra cool is that with hard wired signals, where if I’m transmitting something that is needed by several modules, like some pressure or temperature signal, I normally need to have a wire going to each consumer. But with CAN, this requires nothing extra besides getting the signal on the bus. That’s why the term “bus” in electronics is kind of misleading because it’s really more like an ice-cream truck. Once someone gets off a bus, they can’t do it again. But when the CAN ice-cream truck arrives, every stop can get a cookies and cream if they want it.

AEM has a thorough CAN implementation they call AEMnet and it’s one of the aspects of the setup that sold me. The Infinity, CD7, VDM and EGT controller (pictured above) would all communicate using the same 4 wires (2 signal, power and ground)!

TO BE CONTINUED…

Next time we’ll go into more specifics of what went into my car and how. I thought up some solutions for things that I’m quite happy with. I was also invited to display my car at PRI with Armstrong Race Engineering, so I also ended up doing a few other things that I’d dreamed of for a long time but never got the right motivation.