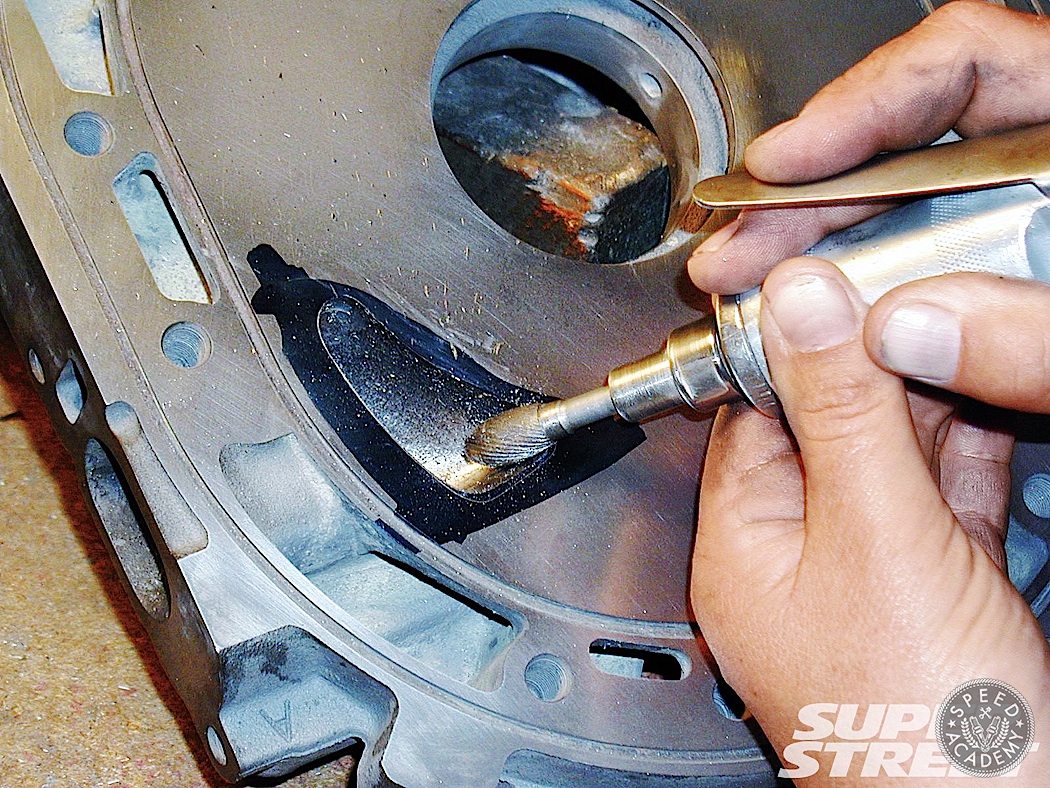

The J port is basically the furthest you can push a bridge port on standard side housings. The eyebrow is thicker and extends past the face of the rotor and into the water seal o-ring area, a step that requires the seal be cut back and filled with a metal sealant like Devcon. And with a so-called monster port (basically the most extreme version of a J port), the eyebrow is much larger and extended well past the rotor housing’s trochoid surface and into the water gallery. This requires the water passage in this area to be blocked off, plus the rotor housing needs to be ‘port matched’ to expose the full length of the eyebrow. The downside to monster porting is that it tends to shorten the lifespan of the engine since cooling is compromised, but the upside is an even crazier top-end.

The last and most extreme type of rotary engine port is called peripheral porting. Since it’s not possible to port the side housings any further than a monster port, a peripheral port approach actually replaces (fills in) the side housing intake ports and replaces them with large circular ports on the rotor housings. This means port timing is no longer determined by the leading/trailing edge of the rotors, but rather by the apex seal passing over the big peripheral port openings. This result is extreme intake and exhaust overlap, which pretty much kills low end performance and drivability (generally don’t like to idle below 2,000 RPM), but the far more direct intake path means you get massive top-end power that’s delivered at 9,000 RPM and beyond.

In fact, it’s not uncommon for peripheral port rotaries to rev to 10 or 11k RPM and make 300-hp in naturally aspirated form, and although coolant flow isn’t as compromised as a monster ported engine, engine life is shortened by the sustained high RPM use its powerband necessitates. That said, peripheral port rotaries are normally a race-only engine setup, so engine life expectancy isn’t the focus, nor is the insanely loud exhaust note, horrendous fuel consumption, or total lack of low rpm drivability. Keep in mind, with a peripheral port setup you also have to run a custom intake manifold, so the cost of going this route is significantly higher than bridge porting or street porting.

But man, as this video clip demonstrates, the sound of a peripheral port 13B or 20B is well worth the price of admission!

A slightly less extreme version is known as the semi peripheral port, which is meant to provide some of that insane top end a full peripheral port setup delivers along with some of the improved low to mid-range rpm responsiveness delivered by side ports. As you can see in the images above, with a semi peripheral port engine, a smaller diameter peripheral port is used in conjunction with a side port on the irons (in a full peripheral port setup the side ports are completely blocked off).

This may sound like a best of both worlds proposition and in some ways it is, but the downside is the need for a complex intake manifold that can feed air to both the peripheral ports and the side ports. Pro-Jay and a few others do make semi pp intake manifolds, though, so it’s not really that big a barrier to entry.

So there you have it, rotary porting in all its flavors, from the mildest of street ports to the wildest of peripheral ports. The intriguing thing (to me, at least) about rotary porting is how it not only improves airflow the same way porting a piston engine’s cylinder head does, but also how reshaping the ports alters timing the way a piston engine’s camshafts do. It’s a two-for-one proposition, which makes it all the more important to either use the most tested and well documented porting templates or outsource the work to a skilled and experienced rotary engine specialist whose learned invaluable lessons through trial and error and real world testing and tuning.

Of course adding rotors never hurts either, as this in-car clip of Mad Mike Whiddett in the peripheral port 4-rotor MADBUL clearly demonstrates!

Engine

building and re–building are considered the nucleus of our business

with standard rebuilds leading the thrust of work. Experience is

crucial, and technique is critical to achieve desired results.

Hi, can anyone tell me who makes the cast peripheral port manifold / throttle body shown in this article?