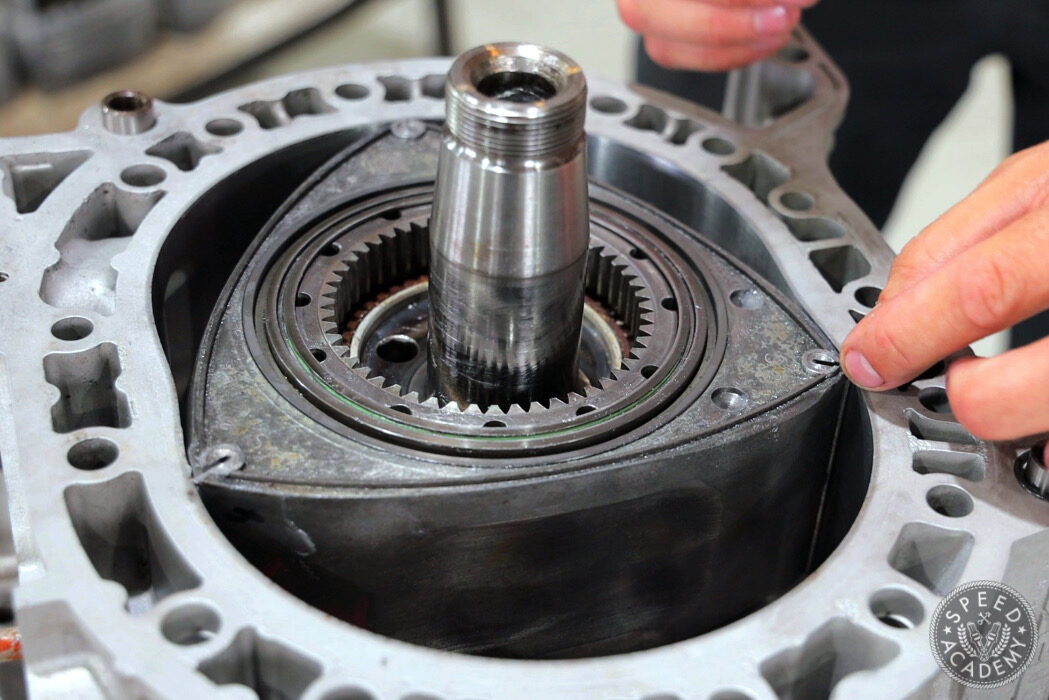

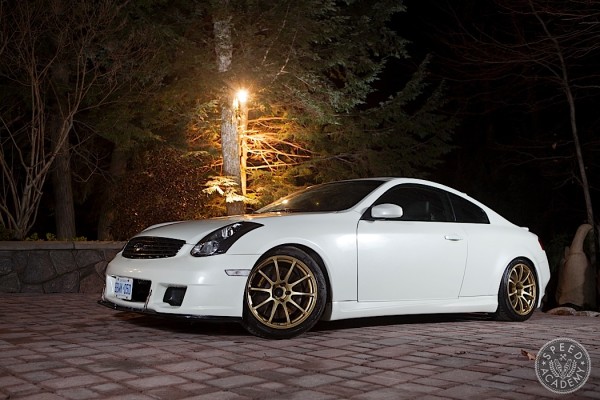

In Part 3 of our 4 part rotary engine build series sponsored by Valvoline, Joe Ferguson from RPM Motorsports completely assembles the 13B-REW shortblock destined for our 1993 Mazda RX-7, demonstrating how to properly “stack” the irons and housings, install the eccentric shaft, and install the Renesis 10:1 compression ratio rotors as well as the iRotary apex seals and springs.

It’s a truly unique process that has very little in common with assembling a piston engine, other than the necessity to check seals clearances like you would bearing clearances in a piston engine (although the process of checking those clearances is totally different, as you can see in Part 2 of the video series).

Once our rotary’s stack was completed, as you’ll see in the video below, Joe then tied the whole thing together using high-strength engine studs from Turblown Engineering. These studs are not only stronger than the OE bolts, but because of their design they also ensure a more accurate and reliable torque setting.

This episode wraps up with Joe installing a baffled and higher capacity oil pan from Xcessive Manufacturing that not only ensures a better supply of oil to the pickup, it’s heavy-duty cast aluminum construction also means it functions as an engine stiffener as well.

Stay tuned for Part 4 of this series, where Pete and I build out the longblock with a whole bunch of sexy go-fast parts.