So that explains why JE designed their rapidly expanding line of off-the-shelf asymmetrical pistons with a larger skirt area on the heavily loaded major thrust side and a smaller skirt area on the less loaded minor thrust side. The advantages of this design are numerous, including a piston that’s lighter and generates less friction since there’s less surface area on the minor side skirt, plus it’s a stronger design as well.

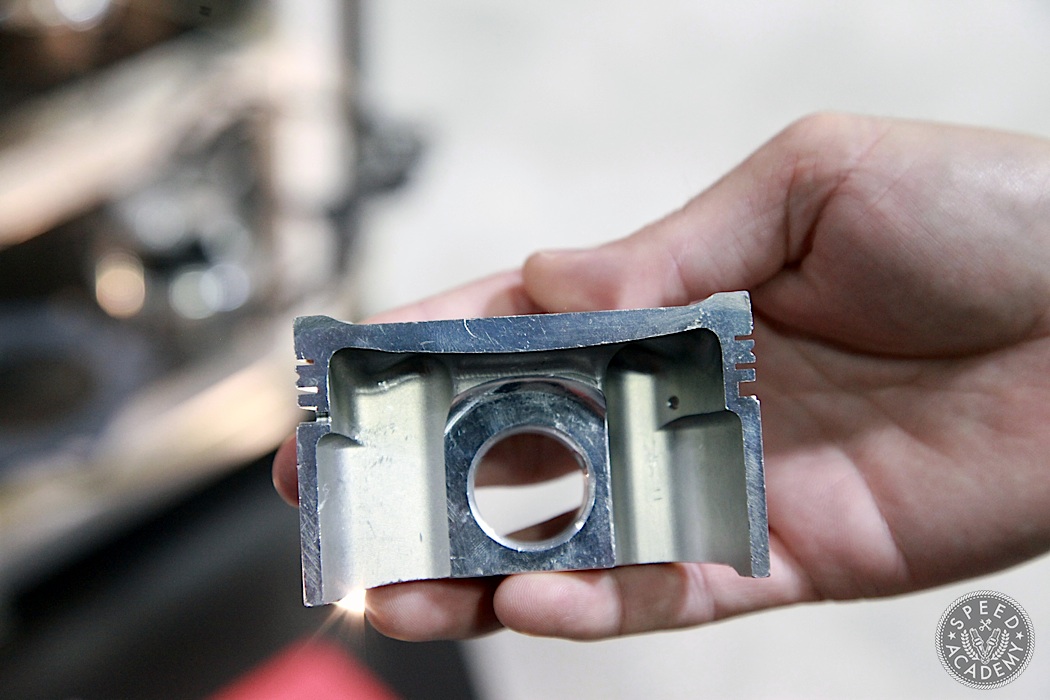

Part of the greater strength of JE’s asymmetrical pistons comes from the fact that it’s a clean sheet design that incorporates a number of new features including a contoured crown thickness. As you can see in the piston cross-section picture above, the centre area of the piston crown is thicker than it is out near its perimeter.

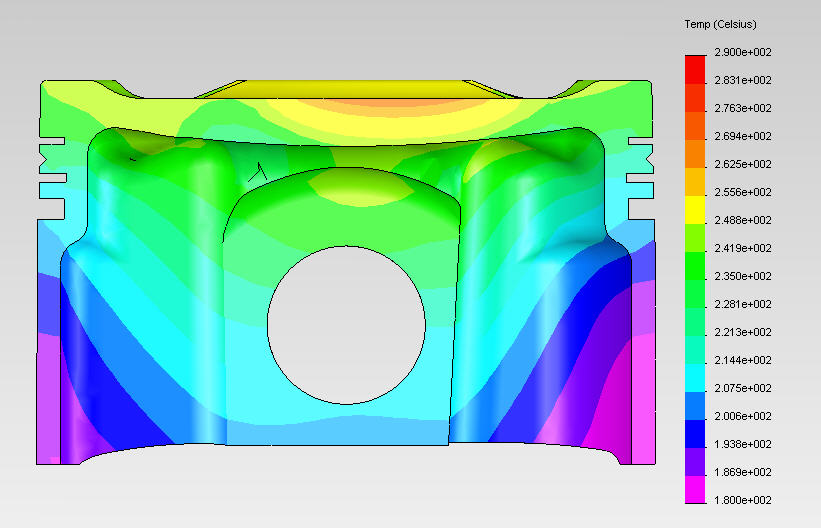

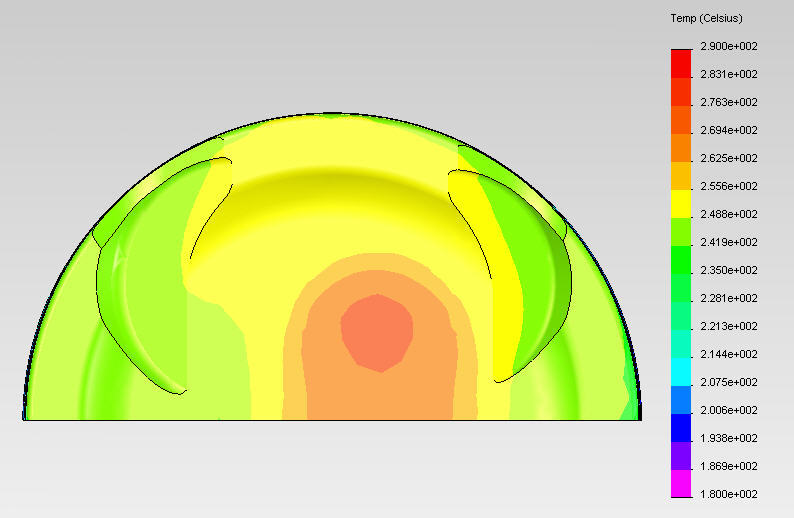

These thermal images from JE show how heat is concentrated in the center of the piston’s crown (orange and yellow ranges) and cooler around the outer portion of the crown (green ranges).

As Sean explained to us at PRI, “The highest level of heat and pressure is concentrated near the center of the piston crown. We found the best way to handle these loads is to create a piston crown that is contoured according to these stress levels. In the location where stress is high (the center) the crown is thicker; in low stress areas the crown is much thinner. This design approach is one reason that JE’s asymmetrical pistons are both strong and lightweight.”

One question that immediately came to mind when looking at the FA20 asymmetrical piston was weight distribution and balance within the piston. Sean had the answer to that too, explaining that they slightly offset the wrist pin toward the major thrust side to position its mass centre inline with the wrist pin centerline. ensure proper balance. By positioning the wrist pin in this way, not only is balance accounted for, it also reduces piston noise, increases piston stability, and improves ring seal. And going back to that clean sheet design approach, JE has used a shorter wrist pin on these asymmetrical pistons, 2.250″ in length as opposed to the more common 2.500″ length used in most sport compact piston designs. That may not sound like a big deal, but when you consider the weight of the pin, which is made of steel, the shorter pin reduces weight by around 10 grams per cylinder.

A few other features worth mentioning with the new asymmetrical designs include the fact that JE’s engineering department created a computerized 3D model of all factory oil squirters during the design phase to ensure proper piston-to-squirter clearance and positioning. Plus the piston crowns now undergo a unique process that produces a smooth finish, where all the edges on the piston crown and valve reliefs are blended smooth in order to reduce the likelihood of hot spots and pre-ignition or detonation.

All in all, we were very impressed by the design and engineering quality of these off-the-shelf asymmetrical forged pistons. So much so, we’ve got all sorts of ideas floating around in our heads about rebuilding the Targa FR-S’s engine for boost so it can run with the big dogs out on rally stages or around the race track. Which really only leaves one question: supercharged or turbocharged?

Oh, and just in case you’d like a review of these asymmetrical pistons direct from the big brains that developed it, here’s a video with Sean offering an excellent design overview.

Turbo it!!!

Turbo for sure! Unless you want it to whine… Like your girlfriend. Oooooo! JK 🙂

LOL no love for the supercharger option, huh? If we rebuild the engine, a turbo will be hard to resist.