With the interior of the car now complete, and even if I do say so myself, looking proper. It was time to start looking at preparing the car to be used at a race track. There were a number of things I wanted to address, first up was being able to monitor, and keep on top of oil temperatures.

A call to Think Automotive resulted in a Mocal remote filter head being delivered, this would be modified to accept the 1/8pt Defi temperature sensor. You’ll have to excuse the tatty oil filter, I don’t have a photo of the setup without it!

Now we begin the saga of dealing with cheap eBay fittings. I would need six AN-8 fittings, and found what looked like a really good deal for fittings and hose. This would be the first time I’d ever made my own high-pressure lines, but had done plenty of research and watching of instructional videos. I thought I had a good idea of what challenges might lay ahead, but as you’ll see that may not have been entirely true.

The small amount of money I saved certainly didn’t make up for the stress and hassle that was involved in attempting to assemble these fittings. Things would start quite well, I’d hand thread one end of the fitting into the other, and then tighten with a polished spanner. The fitting would eventually become almost impossible to tighten down and begin to push the hose out. I disassembled it to find the hose torn to pieces, and some threads damaged on the fitting.

Looking at the above, you’d immediately say, “You’ve cross threaded the fitting, that’s your problem!”. But I promise you I did not, and this happened on 2 other fittings before I eventually gave up and sent them back. I suspect the hose wasn’t compatible with the fittings, or vice versa. Either way, I learned my lesson to not scrimp on parts; buy cheap, buy twice.

I’d end up replacing all of the fittings and lines with Goodridge items and they went together much easier. After my problems with the original fittings, I went to the trouble of having the new ones pressure tested by a local hydraulics shop, passing with flying colours.

With the lines made, it was on with routing them to and from the engine, via the remote filter head and oil cooler. I mounted the filter head up in the void between the bumper and inner arch liner, making hose runs nice and short.

I probably shouldn’t have used a 90-degree fitting here, but it’s all I had at the time. I think a lot of us strive for perfection, and can easily point out something that doesn’t look quite right, I know I can. But often, we have to make due with what we have access to at the time. Small imperfections like this can be addressed in the future, but most importantly it held pressure and wasn’t in danger of being damaged.

With the oil system all buttoned up, it was time to focus my attention on fuel. The race series I’d hope to eventually enter run 45-minute races. There would be no refueling, and with a relatively small 35-litre/9-Gallon fuel tank, I wasn’t sure if the car would be able to complete a race on a single tank.

I decided then to fit a surge tank, which would increase fuel capacity ever so slightly, and allow me to run the tank really low without worrying about fuel surge.

The surge tank is fed by an in-tank Walbro 255 pump, and then a Sytec inline fuel pump would pull fuel from the surge tank to the fuel rail via a Bosch fuel filter. I had the fuel lines made up, replacing the standard hard lines with a full complement of reinforced rubber fuel hose.

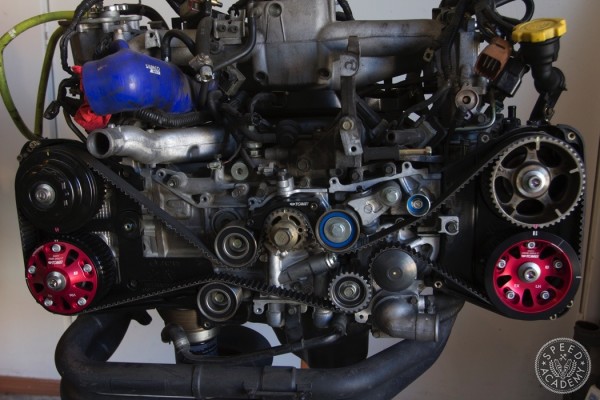

Dean of RW Developments built the surge tank, along with a catch tank, baffled oil pan and a short route intercooler pipe for my now rotated turbo.

The baffles are really simple, and nowhere near as good as a trap door style baffle system, but this would have to do for now. Some baffles are better than no baffles at all.

With the oil pan fitted to the engine, it was time to make some more oil lines and fit the catch tank. It’s quite a smart design, fitting neatly around the passenger strut tower.

I was now ready to start the car. To me, this was quite a big deal, I’d changed a lot of parts, I’d made oil lines for the first time, the fuel system was custom and to my design. In theory, it was all simple stuff, but theory often doesn’t account for rookie mistakes, and/or human error.

I held my breath and turned the key.

Having recently built an engine and started it for the first time, I look back at this video and smile. I really had very little to worry about at the time, the odd leak from an incorrectly tightened fitting wouldn’t be the end of the world. I guess worry or stress is all relative to your personal situation.

After a few months of work, the car was finally ready to be driven again. But first I’d make a trip to a local tuner who would map the car and I would find out how much power the little 1300cc engine would produce. That’s where we’ll pick things up next time…