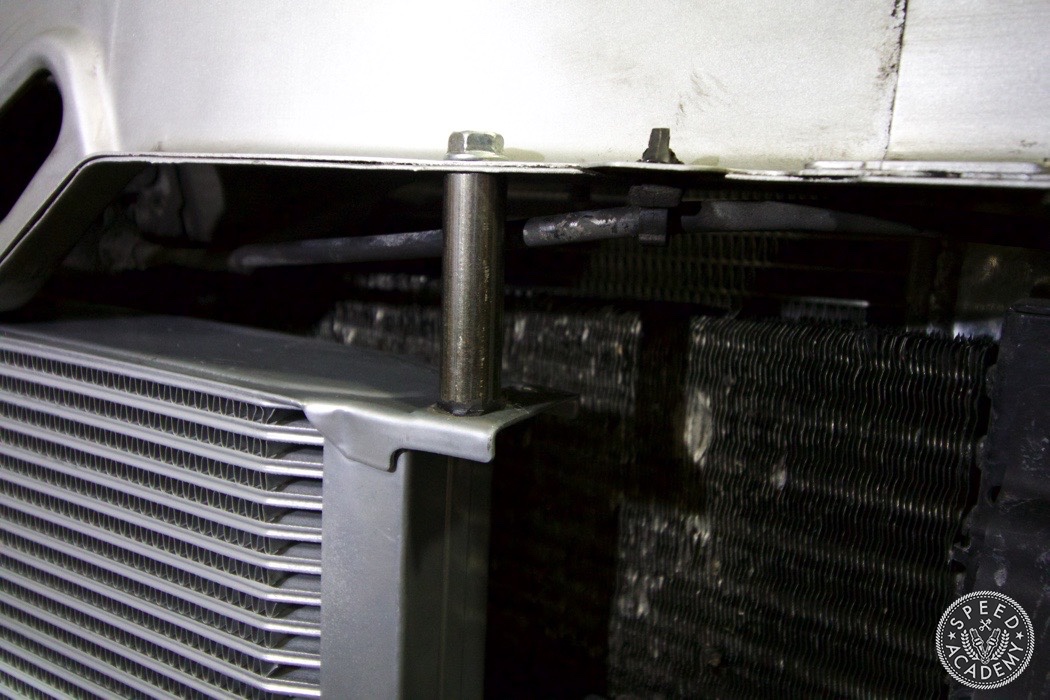

This meant drilling a hole in the upper central rad support for a bolt on the upper passenger side of the cooler, as well as using a rod and a couple of bolts to support the driver’s side top side mount location. Plus we bent up a little bracket to attach the rebar to the lower passenger side mount location. This arrangement provides plenty of support, and we wedged some rubber hose between the cooler mounts and the fasteners to isolate it from vibration.

Next, we fastened the M22 sandwich plate to the engine using the supplied threaded tube, installed the AN fittings and sensors, and threaded on the short oil filter (the standard length oil filter fouls against the Eibach front sway bar with the sandwich plate in place, so we went with a filter short enough to clear the bar).

From there it was just a matter of attaching and routing the oil lines.

Nothing terribly difficult about this job, but as you can see we did take the added precaution of zip tying the lines up to the driver’s side frame rail and we even used some fancy Vibrant Performance line separators to prevent them from rubbing while keeping them cleanly routed together.

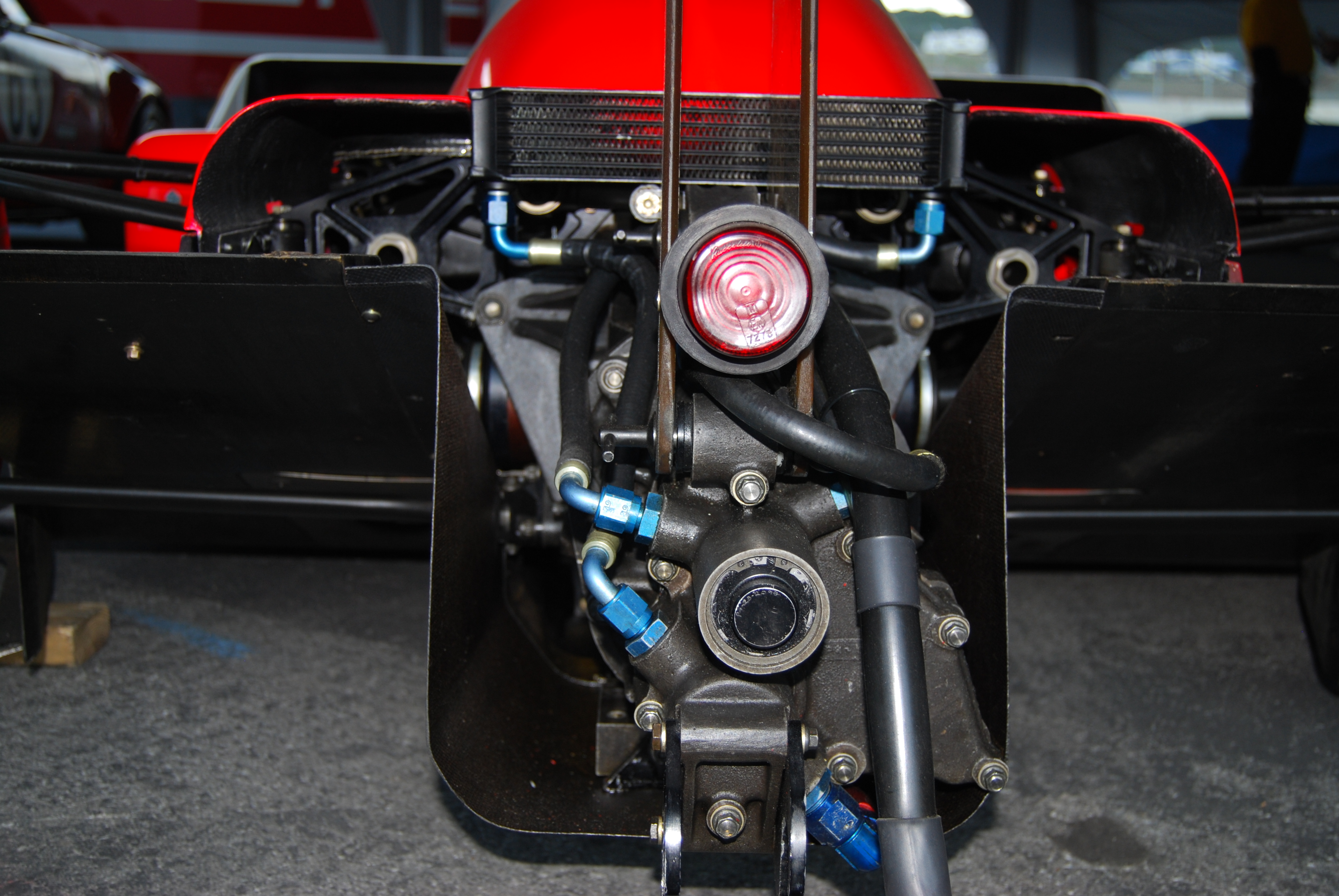

Hey look, the McLaren MP4/2 that Senna drove to multiple F1 championships has an oil cooler with ports at the bottom! It’s magic!

Last but not least, there were a lot of comments on the video below about the oil cooler ports being installed facing downwards. One oil cooler company that we’re aware of doesn’t recommend this (presumably for fear of leaks or having the fittings hanging down too low and potentially being struck by debris), but if installing a cooler with the ports at the bottom is good enough for Mazda on the RX-8 and good enough for McLaren on Senna’s F1 Championship winning MP4/2 from the mid ’80s, it’s good enough for the Mullet Mustang.

Alrighty, enjoy our oil cooler install video, and if you take your car to the track with any regularity we highly recommend an oil cooler if you want to keep your engine’s bearings and other friction surfaces happy and healthy.