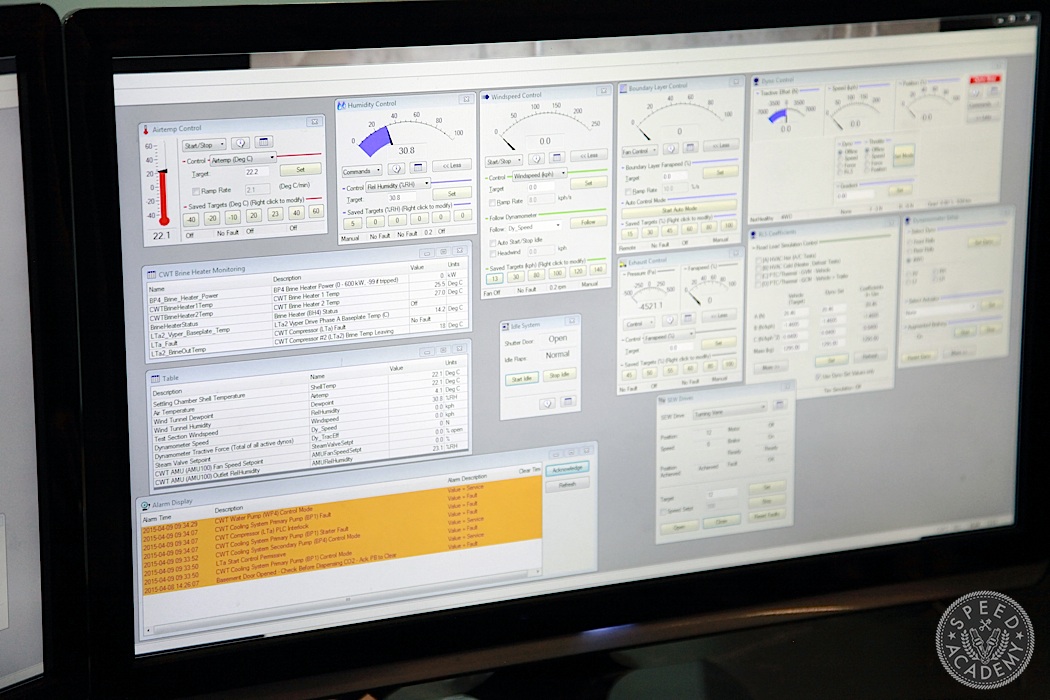

The power needed to generate wind speeds up to 250 kph (the same as a Category 4 hurricane) comes from a 2.5 megawatt, 18-blade, 5-meter wide fan that lives above the main tunnel chamber. There’s a screen behind the recirculation vent on the backside of the tunnel gallery, so cell phones or other loose objects don’t make it to the fan blades. It’s a closed, pressurized system, of course, but the energy needs of a tunnel this big are massive, so a large part of the cost incurred by clients renting time in the tunnel is simply to pay the electricity bill.

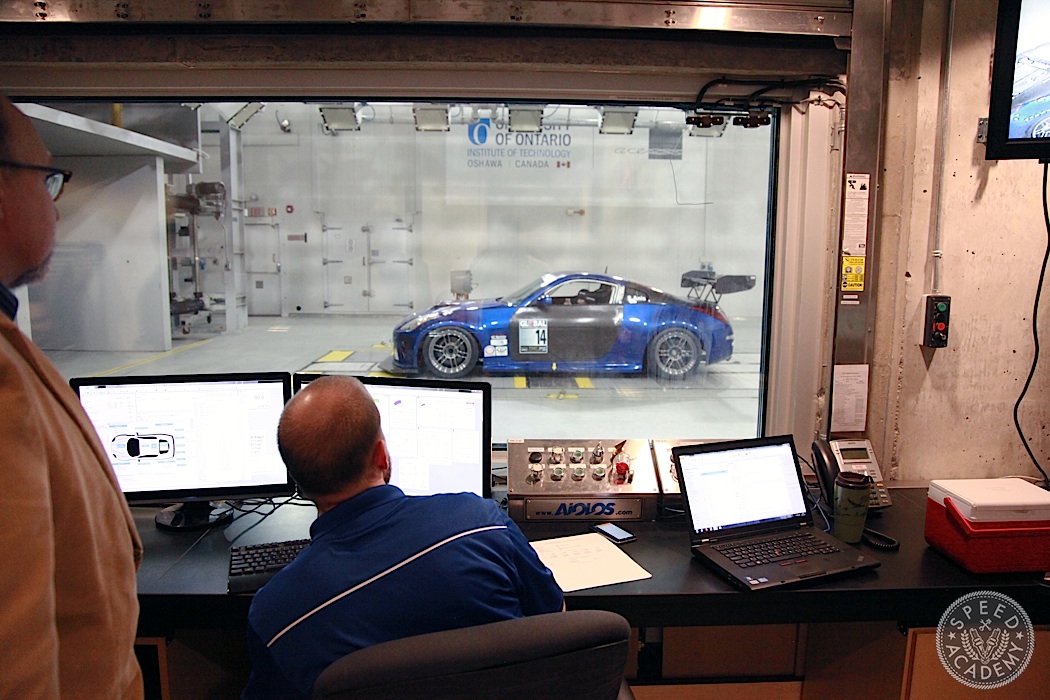

Another component of cost is the staff, all of who extremely helpful and an absolute pleasure to work with. They’re there to help you make sense of the data collected on their bespoke software system, but if you’re an engineer or aerodynamicist they’ll also let you take the lead. You’d be hard pressed to find a more professional or experienced group, Director Gary Elfstrom being the designer of Ferrari’s F1 wind tunnel and Director John Komar having spent years as a aerodynamicist and engineer for companies including General Motors. The passion and enthusiasm they have for ACE and the wind tunnel is easy to see when chatting with them about its inception and construction and about its focus on being a very accessible and inclusive business.

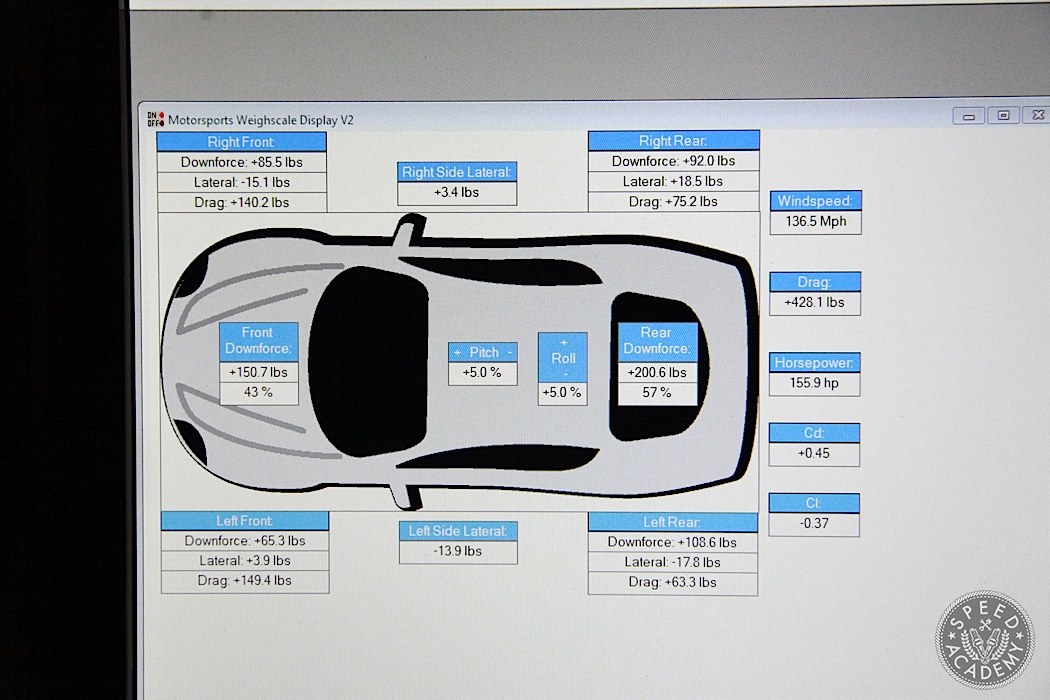

Gary, John and the ACE staff will help you get the most out of your time in the tunnel, but of course it’s also your responsibility to come prepared to maximize your use of this facility. That means being able to make changes to the car’s aero devices quickly and efficiently, and it wouldn’t hurt if you had some idea of how much front and rear downforce your car needs, what sort of downforce/drag ratio you can live with, and that sort of thing. You know, maybe do some reading about race car aerodynamics so that you’re making the most of your $2000/hr investment. Or bring someone way smarter than you along, like our buddy Andrew Wojteczko from Mantella Autosport, whose a race engineer with a big enough brain to make sense of all the tunnel data and help you get your setup dialled in.

So what did we learn when testing Sasha’s Z in the tunnel? Well, you can watch our video recap of the experience to get a sense of how the process unfolded, but Sasha’s also writing a detailed story with all the nitty gritty details for his column in PRN Ignition magazine. Once we know what issue that’s going to be published in, we’ll update this story and share the news on our Facebook page.

Until then, feel free to give ACE Business & Marketing man Colin Howard a call at 905-721-8668 ext. 5777 or shoot him an e-mail at colin.howard@uoit.ca for more information on all their facilities and rates, including the wind tunnel and four-post shaker for testing suspension components. We hope to put the shaker to the test this summer, so with any luck we’ll have a video and story for you on that and lots more cool tech content as we explore the capabilities of this truly world-class automotive centre of excellence.