DI is especially effective when combined with forced induction, which is exactly why we’ve seen a boom in direct injected turbo engines including Ford’s EcoBoost lineup, GM’s Gen V Ecotec engines, and Mazda’s new SKYACTIV lineup of engines (as well as the MZR in the Mazdaspeed3, which will talk a bit more about later). In fact, direct injection is fast becoming the norm in high-output small displacement engines, and it’s even making its way into some larger displacement engines like Chevy’s supercharged LT4 V-8 that we took you on a tour of recently.

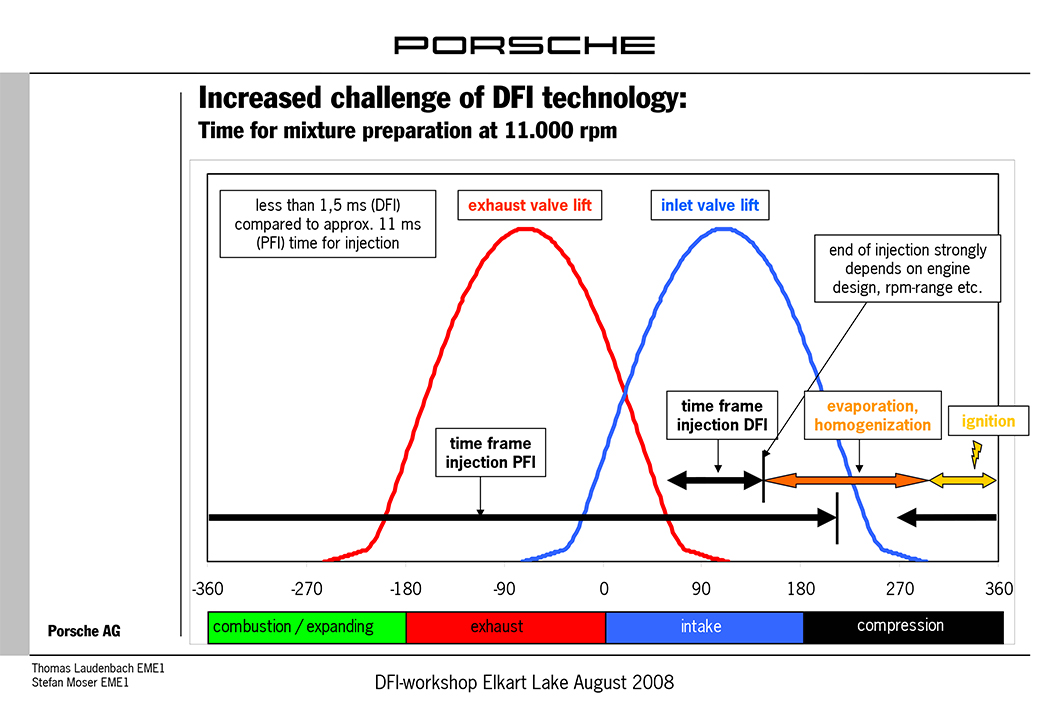

There are some real challenges that come with direct injection, though, including the small window of time in which the injection event must occur and the effects of charge motion as the fuel and air charge collide and mix in the combustion chamber. As Porsche’s 2008 study showed, with port injection there was an 11 millisecond window in which to inject fuel as part of the 4 stages of combustion (see the colour coded events along the bottom of the graph above), but because the injection event happens later in the cycle with direct injection, there was only a 1.5 millisecond window to inject the required amount of fuel into the combustion chamber. These timeframes are extremely tight because this is a race engine at 11,000 RPM, so it’s a bit of a severe example, but it illustrates the point that one of the challenges with DI is injecting enough fuel in a significantly shorter timeframe than available with MPFI. It’s this much shorter timeframe that necessitates the use of high pressure injectors and pumps, but as we’ll discuss in a moment, upgrading the high pressure injectors and pumps is a serious challenge for anyone looking to make a lot more power than the system was originally designed for.

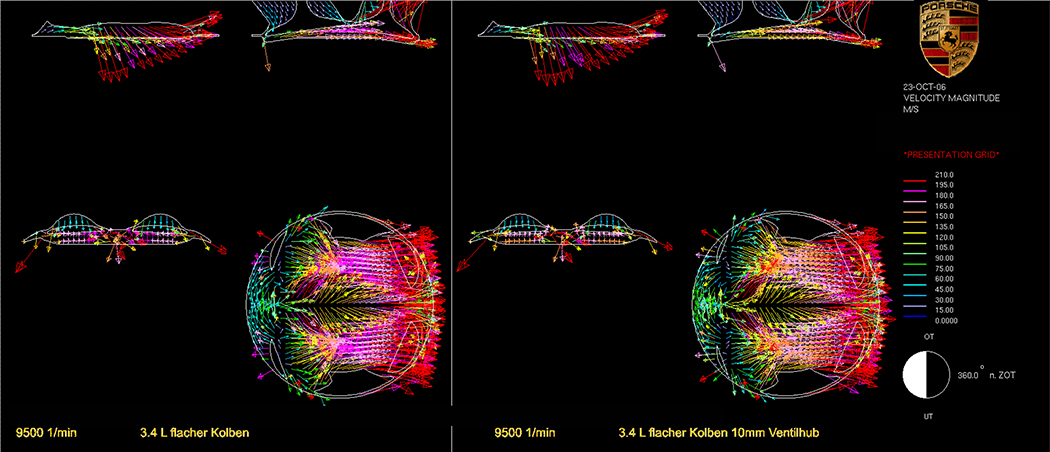

A lot of research has also been done on how injecting fuel directly into the combustion chamber alters charge motion, or the way in which the fuel and air charge interacts prior to ignition. The image above from Porsche’s study gives you a sense of how the air charge hits the fuel and pushes it towards the exhaust side of the chamber. To combat this, DI engine designers have either gone with injection straight down from the top of the combustion chamber, while others inject from the side but use a funky looking piston top like the one above to direct the fuel back up into the center of the combustion chamber and towards the spark plug. As Paul from ID explained, there’s also a huge amount of technology in the tip of DI injectors that’s designed to control the shape, droplet size and velocity of the fuel it sprays (each hole in the tip of the injector having a unique size and complex internal contour), so you can’t just open these injectors up by enlarging the holes or adding more. This would not only disrupt the spray characteristic of the injector, it would also wreak havoc on the atomization process, to name just a few of the potential pitfalls here.

Source: http://www.drivingenthusiast.net/sec-mazda/products/mazdaspeed3/images/MAZDA3_engine_HR.jpg

For us power-hungry tuner-types, the good news is that in most cases the fuel tables, ignition advance, camshaft advance, boost control and other ECU controlled parameters are more or less the same as we’re accustom to seeing when tuning a port injection engine. But the bad news is that things get more complicated in a hurry once you’ve maxed out the fuel pump or start running into other bottlenecks in the engine’s design. Cobb Tuning ran into an interesting example of this with the first gen Mazdaspeed3, as Trey Cobb explained to me back when I first researched DI for a magazine story. As he told me, “With respect to the Mazdaspeed3, the next hurdle to overcome is the camshafts. The 4-cylinder MZR engine is not designed to operate at a very high engine RPM range, due in part to the limitations of direct injection. There simply isn’t as much time to inject fuel per cycle as there is with non-DFI setups, thus lowering your maximum RPM ceiling. The camshaft profile for the MZR motor was designed specifically for lower to mid-range power output, and the engines are tremendously efficient in that range. Even with upgraded turbos and manifolds, the engine’s volumetric efficiency decreases significantly at higher (6000+) RPMs. HP is dependent on RPM, however, so in order to get the HP numbers people are looking for, a solution needs to become available to shift the MZR’s VE up in the RPM range. That will involve (I suspect) different camshafts and potentially higher flowing injectors in addition to the normal supporting modifications (fuel pump, turbo, manifold, intercooler, etc). The limitation of time to inject fuel at high RPMs will still exist however, as that’s inherent to the nature of DFI systems.”

Source: http://image.hotrod.com/f/88524256+w660+h495+cr1/comp-cams-direct-injection-pump-lobes.jpg

Source: http://www.compperformancegroupstores.com/store/graphics/00000001/Lobes3.jpg

Here you can see how the square camshaft fuel pump lobe interfaces with the mechanical high pressure fuel pump above it. Source: http://www.full-race.com/img/articles/Mustang-2015/Ford-Mustang-GDI-3.jpg

Paul from Injector Dynamics also explained that the fuel pump is typically the first component to be maxed out with DI systems. Unlike MPFI systems which typically use an electric fuel pump, DI systems use a positive displacement pump that’s tied directly to engine speed via the camshafts. With maximum fuel delivery configured to peak torque, the only way to overdrive the pump is to change the camshaft to one with a more aggressive fuel pump lobe. Comp Cams, for example, makes different DI pump lobes for the LT1 camshaft in the C7 Corvette, but as Paul explained, if the camshaft also has more valve lift and duration, suddenly you may also have a scenario where that extra few mm of lift may push the valves into the carefully engineered path of the fuel as it’s injected into the combustion chamber. Point being, DI is an extremely complex system with a lot of inter-related parts, so something as seemingly simple as increasing output from the fuel pump can turn into a much more complicated affair that should really include recalibrating the ECU to adjust for the change in flow and pressure.

Source: http://paceperformance.com/images/F120705149.png

The C7 Corvette crowd has also used the higher pressure LT4 Z06 fuel pump when adding forced induction to the LT1, increasing max fuel pressure from about 2100 psi to 2900 psi. This $1000 upgrade gives the LT1 guys the added fuel pressure they need to make big power, but the question remains how installing this larger pump impacts on the rest of the system. For example, Paul from ID pointed out that a lot of work has gone into controlling pulsations in the OE fuel system, and it’s really not clear how changing the pump (or other components) will effect overall pulsation attenuation. If pulsations are more pronounced than the system was originally designed to handle, the lifespan of the pump or even the engine itself could be shortened (the pump has a sort of blow-off valve to deal with spikes in pressure, but it’s not designed to survive frequent use). Point being, these are still early days in the development of direct injection, so early adopters and modifiers are taking on some risk when changing the camshaft, cam fuel pump lobes or the pump itself.

Source: http://cdn3.volusion.com/rnmwa.rjxsk/v/vspfiles/photos/E048-07-121-2.jpg?1394710558

A cross-section of the 2.3L Ecoboost DI injectors used in the Ford Mustang. Source: http://www.full-race.com/img/articles/Mustang-2015/Ford-Mustang-GDI-4.jpg

As for high pressure fuel injector upgrade options, those have been slower to emerge from the aftermarket. Going back to Paul’s point that DI injectors are extremely advanced and heavily engineered with respect to spray pattern, it’s not as simple as boring them out to flow more fuel. There’s still a lot of R&D going on in the DI injector field and the technology is heavily guarded, so the only upgrades I’ve seen so far is to use OE injectors with a higher cc rating, such as swapping the LT4 injectors into LT1 engines or Mountune’s 1250cc injectors for the 2-liter EcoBoost in the Focus ST that are presumably from a 2.3L Ecoboost.

Source: http://www.oilem.com/wp-content/uploads/2014/07/Audi-RS4-Inlet-Valve-Carbon-Buildup.jpg

With direct injection expected to be in use on at least 25% of all cars by 2020, this high pressure, high tech approach to fuel injection is here to stay, but there’s still a few bugs to be worked out. All you have to do is Google “direct injection problems” and you’ll find a ton of discuss about carbon build up on the backside of the intake valves, causing hard starting and random misfire codes. This build up is cleaned off with MPFI, but since DI doesn’t spray any fuel on the backside of the valves, carbon can start to build up in as few as 3,000 miles. This can start to hurt engine performance and lead to turbo or catalytic converter damage as bits of the carbon deposits break off and enter the exhaust. Audi/VW and BMW have struggled the most with this issue, which seems to be traced back to the engine’s breathing system and PCV valve in many cases, but engine calibration (fuel timing), fuel spray pattern and valve seat design are also thought to be contributing factors. Ford and GM seem to have a better handle on the carbon build-up issue, but the point is that if the OEMs are struggling with an issue like this, you know the technology is still in its infancy, relatively speaking.

Source: http://www.stratifiedauto.com/images/Aux%20Fuel%20System/Stratified%20Xtra%20Fuel%20System.JPG

One aftermarket solution we’re starting to see more of is the addition of port injection to DI engines, like the Stratified Auto kit for the Focus ST. This could well be the approach the aftermarket focuses on until DI technology advances to the point that it can be modified in a more complete and OE-like fashion, but there’s no getting around the fact that DI is here to stay. In a world demanding better fuel economy and lower emissions, direct injection offers the level of precision needed to deliver both, and with the added benefit of greater power output as well. And as for owners of DI vehicles, you guys are living in a brave new world and we’re certainly looking forward to seeing how the OEMs and the aftermarket respond to your need for more fuel and more power.