That leads us up to 2015 and where the car is today. I had a chance to catch up with Sasha and take an up close and personal look at the 350Z as it sat hibernating in his garage during our cold and long winter.

Most of the stock body remains but as I just mentioned before, the roof and doors have been replaced with custom built carbon examples to shed weight.

The front splitter is the same as the original splitter from 2008 that has been extended by C3 Composites and protrudes up to 4 inches with side fences and front wheel arch deflectors that push air around the wheel. I’ve actually been seeing this design on many of today’s latest sports cars including the new Corvette Z06 so it’s got to be an effective mod.

The DJ engineering dual flap wing spans 71-inches wide and rises up level with the roofline – similar to the rules of an ALMS GT car. It’s mounted directly to the chassis through the carbon hatch on some aluminum stays that Sasha designed.

The wheels are Enkei RPF1‘s in 18×10.5 sizing with Michelin 27/65/18 slicks while an upgraded Stoptech ST-40 brake kit handles the stopping duties up front and stock 350Z brakes remain out back with upgraded pads and rotors.

Forget license plates! This Z has a cutout that houses the engine oil cooler, differential cooler and fan.

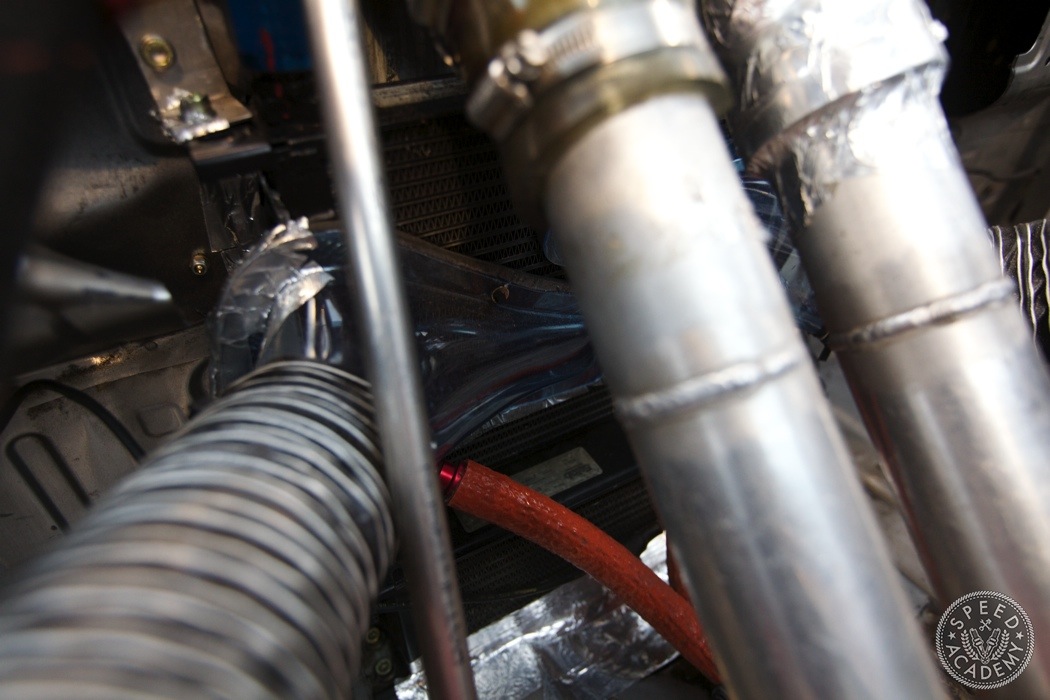

Through some clever ducting, the engine oil and diff cooler gets ample fresh air at high speeds when the fan can’t keep up. This was a last second modification I helped Sasha with at Global Time Attack Road Atlanta when the oil temps were getting a little out of control!

Being that it was an endurance car in Koni Challenge the car had a trunk accessible dual dry break. Sasha re-located the dry-break to the rear hatch so that refueling could be done without having to open the hatch. While it would be lighter to run without it, a dual dry break is a staple of a true GT car and there is always the possibility of Sasha running longer endurance races with the car.

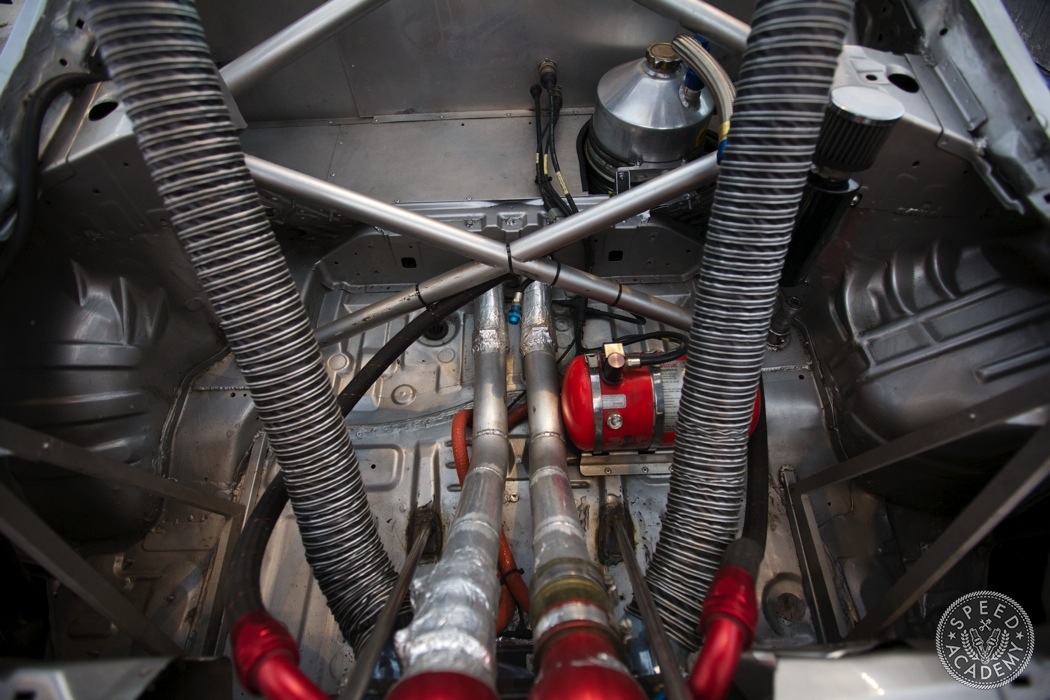

The other notable item in the rear trunk area of the 350Z is the Peterson oil tank for the Dailey dry sump pump. It’s located back to keep the weight down and over the rear axle.

This firewall was originally built by Unitech when the car was new, and now serves a dual purpose to protect the cabin from both fuel and oil lines.

Inside the rest of the interior you’ll find only the essential tools needed to go fast.

Does the engine in this car still retain the vq35 block with a vq37 crank swapped in? if so how was that possible?