Of course if you want the ultimate in wheel strength-to-weight ratio, a forged wheel like the Volk Racing CE28N RT we ran on our Scion FR-S for Targa Newfoundland or the BBS LM’s on Pete’s Evo8 are very hard to beat. That’s because the forging process produces an alloy that is denser and with a superior grain structure than casting, and as a result less alloy is required with a forged wheel to achieve the targeted strength, rigidity and load rating.

There are two main methods of manufacturing forged wheels: mold-form forging like Rays uses and machine forging like many of the “boutique” aftermarket wheel companies use. As the images above and video below illustrate, the form-forging process used by Rays places a solid piece of billet aluminum between two forms (that define the shape of the wheel) and then places the billet under tremendous heat and pressure on its 10,000-ton forging machine. This forging machine, the largest in Japan, enables a wheel with a high forging ratio to be molded in a single pressing.

As this video shows, the pressed forging is just the first step in the production of a finished forged wheel from Rays, and in some cases their forged wheels undergo what Rays calls RM forging which appears to be a flow forming process that allows them to take even more weight out of an already remarkably light and strong pressing. There are a number of other steps that Rays takes before their forged wheels are 100% complete, including heat treating and machine work the finishing touches like logos.

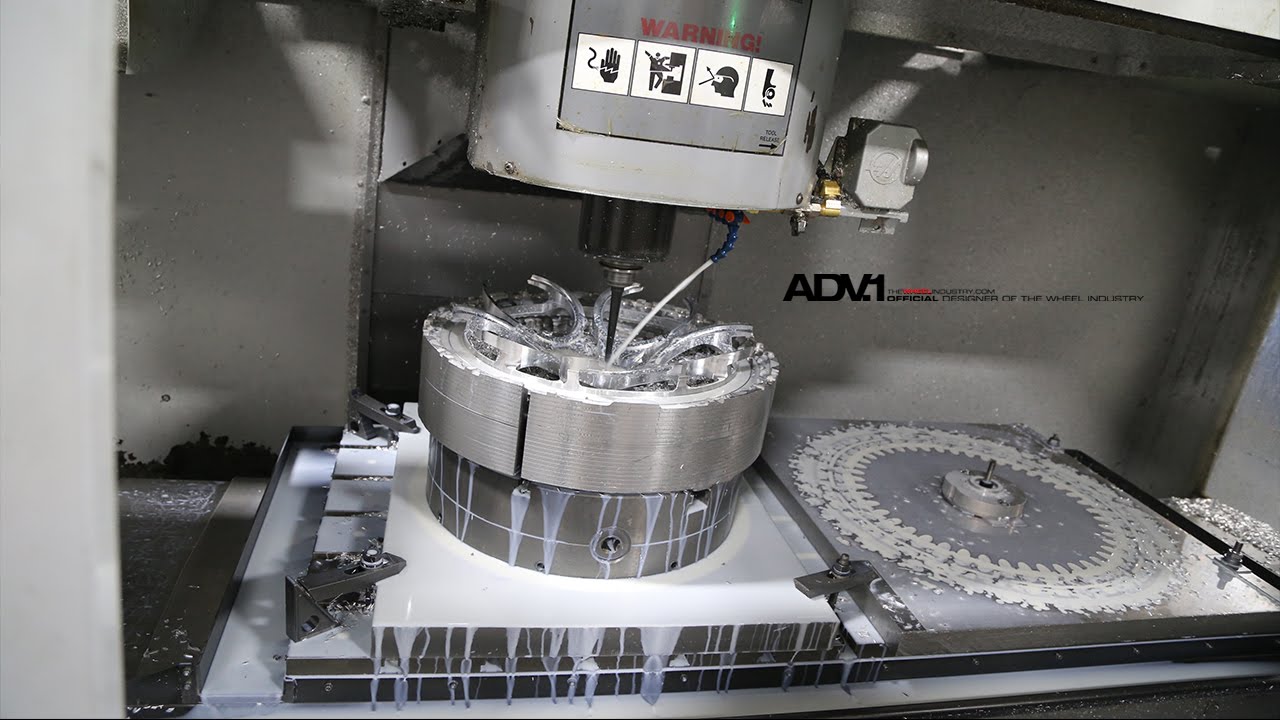

What’s most important to understand about the mold-form forging process is that it allows the alloy’s internal grain structure or fiber flow to follow the shape of the wheel, producing greater strength and elongation properties than a machine forged wheel. With machine forging, the wheel shape is cut on a CNC mill from a block of forged aluminum. This block has its grain structure defined when it’s forged prior to machining, so when the wheel is cut from the block, the grain structure or fiber flow cannot be changed to follow the shape of the wheel. A well engineered and designed machine forged wheel should still be lighter and stronger than a flow formed or cast wheel of the same size and specs, but it won’t quite have the same rigidity or elongation properties of a mold-form forged wheel.

To be clear, a properly designed and manufactured wheel is going to be perfectly safe on your road car regardless of whether it’s cast, flow formed, or forged. All other design parameters being equal, you simply gain the advantages of less weight and greater stiffness and elongation should you decide to step up to a flow formed or forged wheel.

A final issue worth discussing in some detail is wheel load rating, which is normally determined by the wheel manufacturer by dividing the vehicle’s heaviest gross axle weight rating by 2. If you’d like to know what your car’s gross axle weight rating is, this information is displayed on the identification label located on the driver’s side door jamb, gas tank door, truck lid or in the glove compartment, although it won’t tell you which axle carries more weight. But if you look at your vehicle’s weight distribution (a stat that is easy to look up online), you can look at the load rating on the wheels you’re planning to install so that you’ve got a very good idea if you’ve got a wheel load capacity with enough safety margin to meet your needs.

Just keep in mind, these are static load rating numbers and if you’re going racing or doing some seriously spirited canyon runs, the extra strength, stiffness and elongation properties of a flow formed or forged wheel will give you superior performance out of the tire and offer greater safety margin against the kind of complete wheel failure we’ve seen from lesser wheels.

To come at the load rating issue from another angle, if you start to dig a little deeper on this spec (which is often indicated on the back of a wheel spoke), you’ll discover that this is not an actively reported or marketed metric in the wheel industry. Why is that? Maybe some wheel companies don’t want to release a spec that could potentially confuse or lead consumers in a different direction, or it could be that some companies simply don’t consider load rating a relevant consumer metric but rather a manufacturing parameter to be used by their designers and engineers. Whatever the case may be, as a racer I certainly want to know that the wheels going on my cars, especially if they’re going to see track time, have a serious safety factor built into their designed load rating as well as the best possible construction characteristics (like weight and elongation) my wallet can handle.

Simply put, there’s only one way to take weight out of a cast wheel and that’s by removing material, so there’s reason to be concerned if you come across a cast wheel that weighs the same as a flow formed or forged wheel. Because as I’ve already covered, with flow forming or forging you can use less material because of the strength of the alloy produced by these methods, so for a cast wheel of the same size to approach the weight of a flow formed or forged wheel, you have to understand that strength and load capacity are most likely being sacrificed.

We understand that the hobby of modifying your car can get expensive, and the hobby of racing can empty your wallet faster than Joel Osteen during a flood. But there are places to focus your resources when building your street car or track car, and for us, wheels are at the very top of the list. Thanks to the growing number of high-quality flow formed wheels on the market, you don’t have to bankrupt yourself to equip your whip with some strong and lightweight rollers, and for those of you who want the absolute lightest and strongest wheels money can buy, a mold-form forged wheel offers the ultimate strength-to-weight ratio.

Shop wisely, know your budget, do your homework, and be aware of the wheel’s load rating if you’re buying at the low end of the price range and be doubly aware of its construction, load rating and reputation with racers if you plan to use it as a track wheel. Be safe out there, and we hope to see you at the track soon!

Great read, absolutely wonderful!

Great read, really interesting to finally know what all of these mean. Have always been curious, but didn’t want to scour the internet for all of this haha.