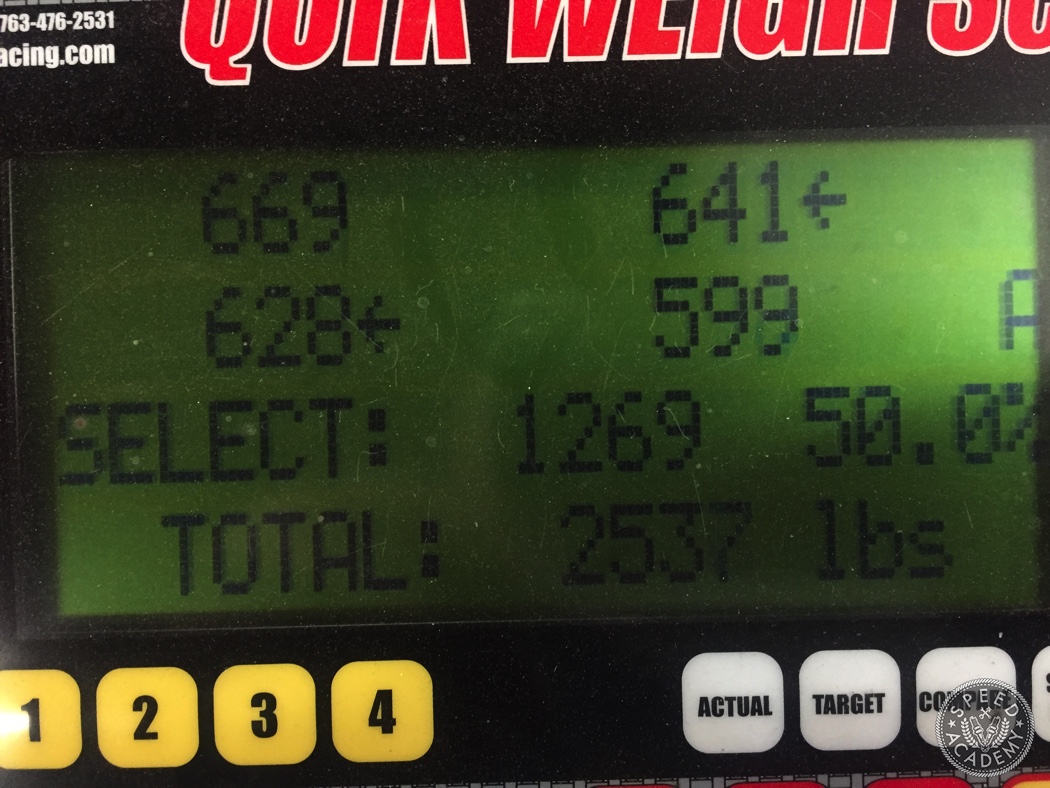

From there, we paid Scott at Can Alignment a visit to get the car corner balanced and aligned. For those curious, the car’s final weight is 2400 lb with a quarter tank of fuel.

Considering other upgrades, the car’s received like it’s rollbar, it’s safe to say that it weighs about the same, post swap.

Alright, I lied – we weren’t done. Turns out that with these wheels at this ride height, there were rubbing issues that needed to be addressed. For that, I paid Chris, the owner of Burning Rubber Tire and Speed a visit for fender rolling.

It’s worth mentioning that last year, the car received a set of XIDA coilovers from 949 Racing, a Racing Beat front sway bar and Hawk HP+ pads, so from a suspension and brakes perspective, we were covered. That was until I handed my car over to Mr. Dave Pratte.

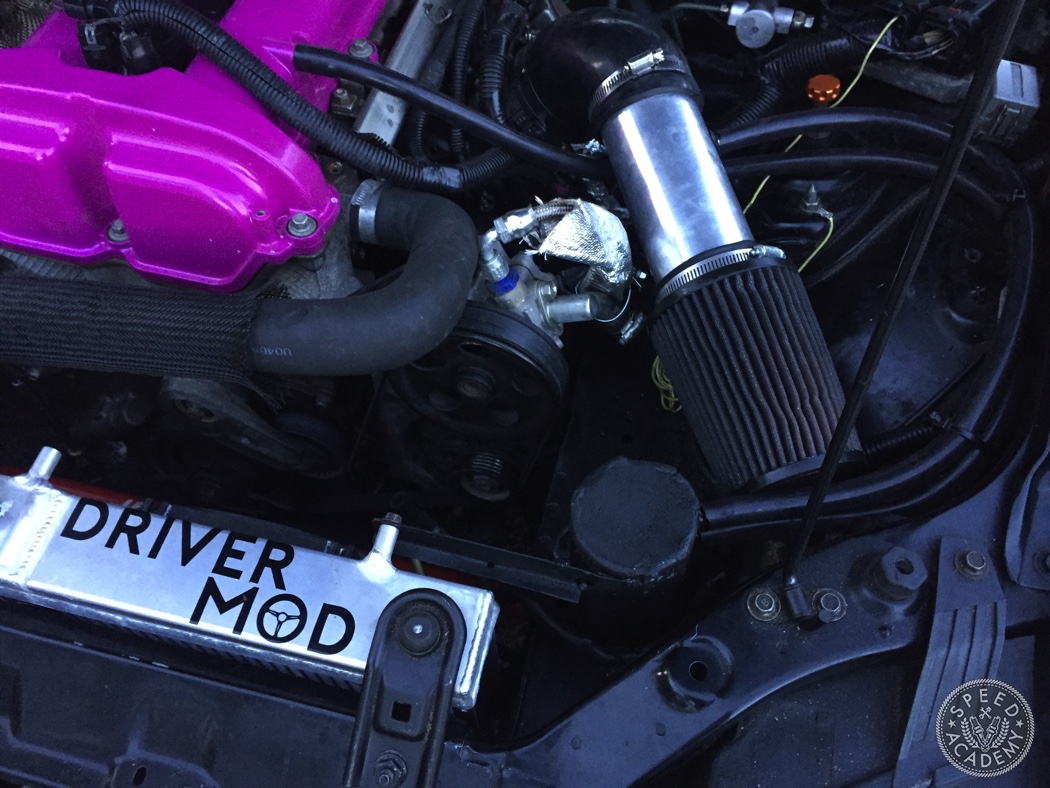

After our track test, I walked away with some awesome feedback. For one, oil was leaving the engine’s PCV valve and pooling in our intake tube. According to Ecotec Miata, if you’ve sealed the centre vacuum port in the intake manifold (also covered in part 2), this should not happen, so there’s a good chance that ours is not sealed correctly.

In any case, adding a catch can is never a bad idea, so Rajan from R Theory Motorsports kindly fabricated me up this catch can that fits neatly in the engine bay.

Another problem was heat soak. That car felt noticeably down on power after five-or-so laps and engine bay temperatures got noticeably high after a session. The ideal solution to this problem is a cold air intake, but as all Miata owners know, there simply isn’t room to route one. We added titanium heat wrap to our header to bring temperatures down, and the car’s more-than-likely going to receive a set of R Theory Motorsports hood vents, along with heat shielding for the intake filter.

Then there are the brakes. With stock power and stock suspension, the HP+ pads the car wears were more than adequate. But in its current state, we’re now pushing deep into the low 1:20s around TMP and things are getting hot. Once these HP+ pads are finished, it’ll be receiving brake pads with greater heat tolerance.

Finally, I noticed that our AEM wideband was suddenly lean at idle following our lapping day. Further inspection revealed that both exhaust gaskets in our Manzo USA header had disintegrated; the second time this has happened. The plan is to weld the header, where the 4-2 piping meets the 2-1 piping, together, and replace the lower downpipe gasket with a Vibrant gasket. Pro Tip: the Manzo USA header we used work great in this application, but their gaskets aren’t reliable for track use.

Phillip Oliveira is a local track day junkie who spends his days running the Canadian car culture journal DriverMod, and his nights awake wondering if his Ecotec-swapped Miata will ever be finished. You can see more of his work at www.drivermod.ca.