As you can see, the Professional Awesome crew didn’t spend gazillions of dollars on custom carbon fiber aero or Voltex-everything. This is grassroots aero at its finest, built primarily from Alumalite, a strong composite panel with a high-density corrugated polyallomer (CPA) core and baked polyester aluminum faces. It’s a lightweight, rigid, and affordable material choice, perfect for aero mad scientists on a budget. And those DTM-inspired fender flares are clearly hand-formed from sheet metal, so don’t expect to find replicas on eBay any time soon, kids.

This isn’t Dan (it’s photographer Paul Kapoor), but it gives you a good idea of how far back the driving position has been moved.

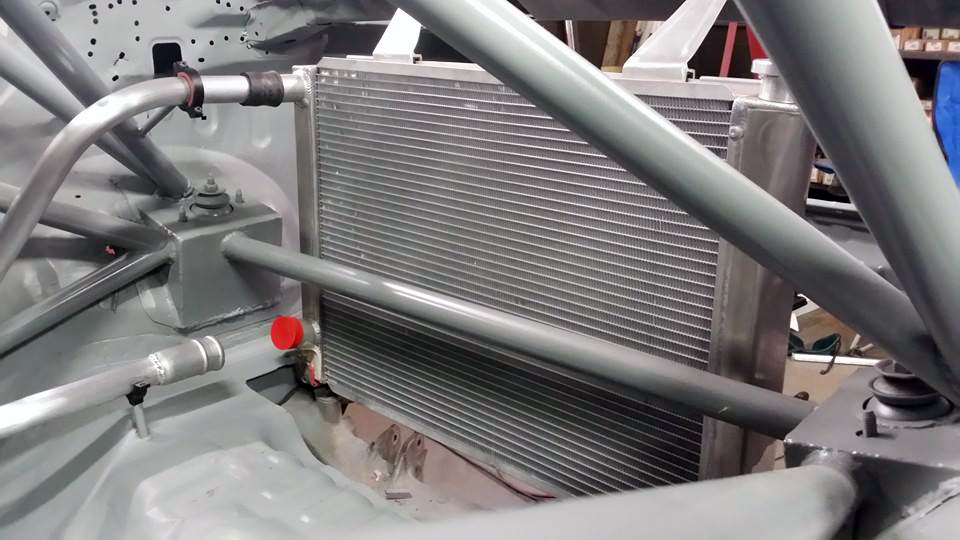

Rear mounting a radiator is never easy, but it allowed the team to centralize weight and improve the car’s polar moment.

Starting from scratch also allowed the Professional Awesome team to make some pretty radical changes to the chassis and cooling package. As Dan explained, “We focused heavily on shifting weight to the middle of the car to reduce its polar moment of inertia. Because of this, we moved the driving position as far back as possible, took the radiator from the front of the car and moved it in between the rear shock towers, removed the power steering pump and ran a MR-2 Spyder unit in the cabin. There were also countless other tweaks and ideas that I can’t remember anymore!” For those of you assuming “can’t remember” is racer-speak for “it’s a secret”, nothing could be further from the truth. One of the coolest things about the Professional Awesome crew is just how open they are and how willing they are to share what they’ve learned.

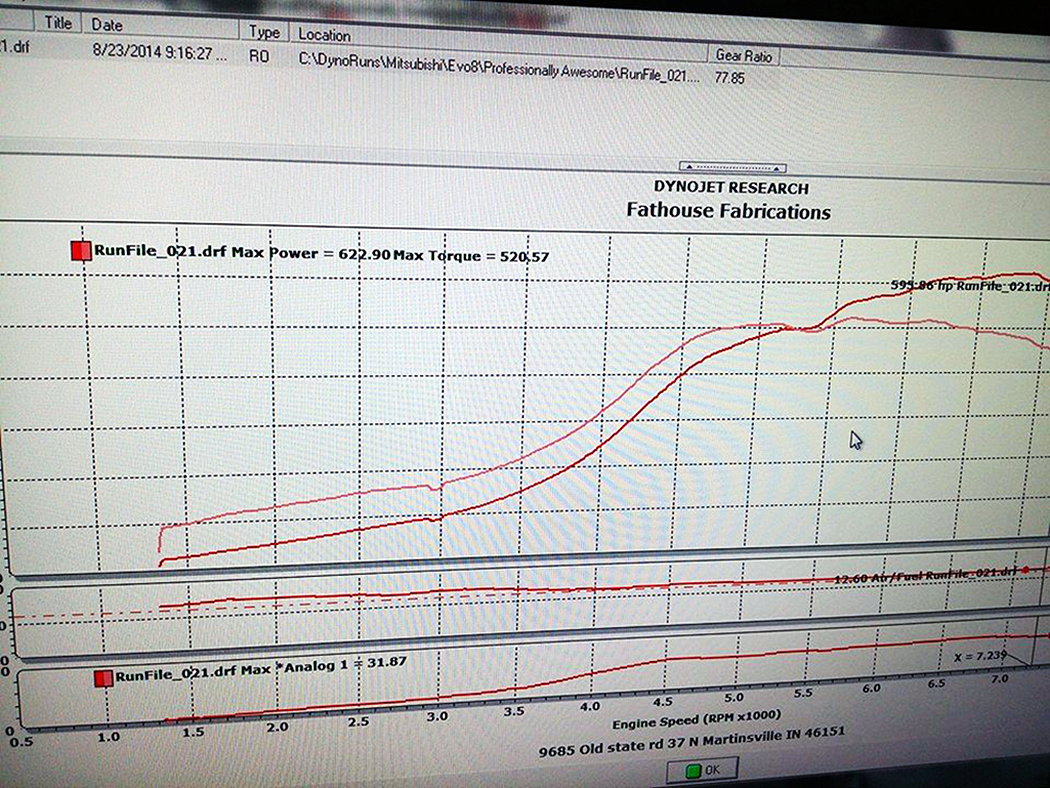

As an example of their openness, they posted a dyno graph to their Facebook page when most teams won’t even look you in the eye when you ask them about horsepower. Pretty impressive what a 4G64/63 engine with a Garrett GTX3582R can do with Tony Szirka from UMS Tuning fine-tuning the maps on the AEM Infinity 6 ECU. Lean in and squint and you’ll see 622.90 as the peak HP figure, and this was just an initial tune, so we’re betting there’s a bit more to come from this engine once it’s fully dialled in on E85.

Speaking of ethanol, it’s worth mentioning that Professional Awesome uses a Zeitronix ethanol analyzer that, according to Dan, saved the engine from a bad batch of “E85” once. “It turned out to be E30-35 and if we would have run it previously, it would have been a big problem. The Zeitronix analyzer integrates perfectly with the AEM Infinity and combined, the ECU will automatically compensate boost, timing and fuel pulse width to properly match the fuel. Truly magic!”

Professional Awesome’s plan was to test the car earlier in 2014 and really show its full capabilities at the SLB Finals, but the build took longer than expected, so they only got a single day of testing in at their home track of Gingerman Raceway in South Haven, Michigan. As Dan told us, “We had two days of testing scheduled and the first day was magical. I mean, really amazing. There were no issues other than the track having too many cars on it and not being able to get a clean lap because I would catch the cars up ahead too easily. We unofficially broke the TTU record in the first session of the day, the first time I ever drove the car, on 2 year old used tires, with a terribly screwed up brake bias that we didn’t figure out until Buttonwillow. The car was that fast, and the Fortune Autos [Dreadnought Pro 2-way adjustable coilovers] were shocking (no pun intended). Only minor tweaks to rebound and compression were needed and the car was extremely compliant but also in control. Now the only issue is dealing with body roll from the added grip! The second day was a different beast all together, though, with a fuel supply issue that we couldn’t fix at the track. So that was it, one day of testing before putting the car on a trailer and shipping it to California!”