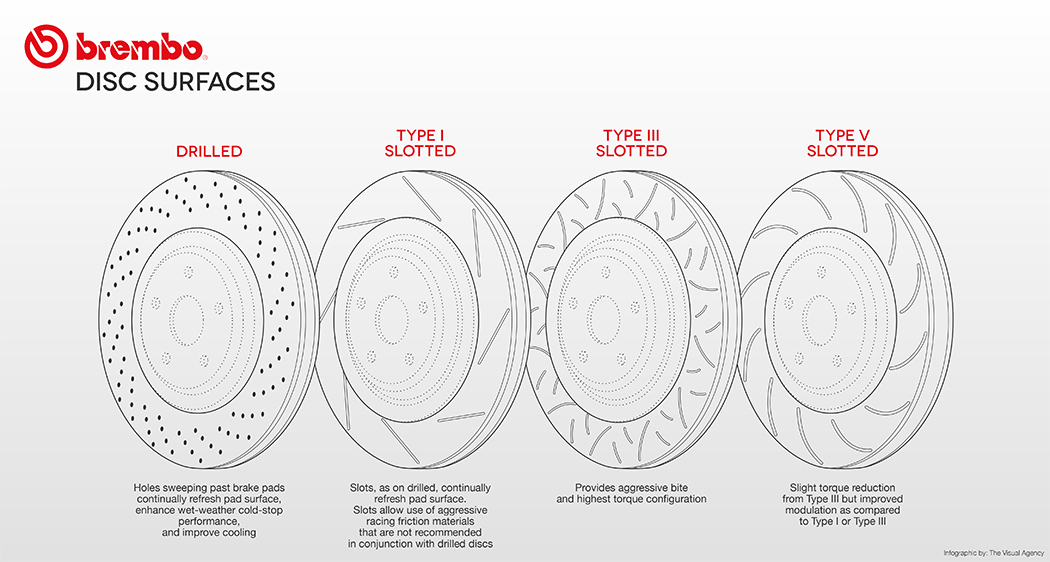

Perhaps the most eye-catching feature of a high-performance rotor is the slots and/or drilled holes in its disc face. As many of you already know, cross-drilled rotors came into being because of the need to evacuate gases or water from the interface between the disc face and the brake pad surface. However, modern brake pads don’t have an issue with out-gassing like they did in the past, but as Mark from Brembo explained, “cross-drilling is still helpful for use in wet conditions, especially when the pad surface area is large. Additionally, cross-drilling increases the surface area of the disc, and this aids in disc cooling (one factor in brake disc cooling is the ratio of surface area to disc mass). The most significant feature of the holes (when done correctly) is that they continually refresh the brake pad surface, providing improved performance and greater disc life.”

DBA XS Series drilled and slotted rotor

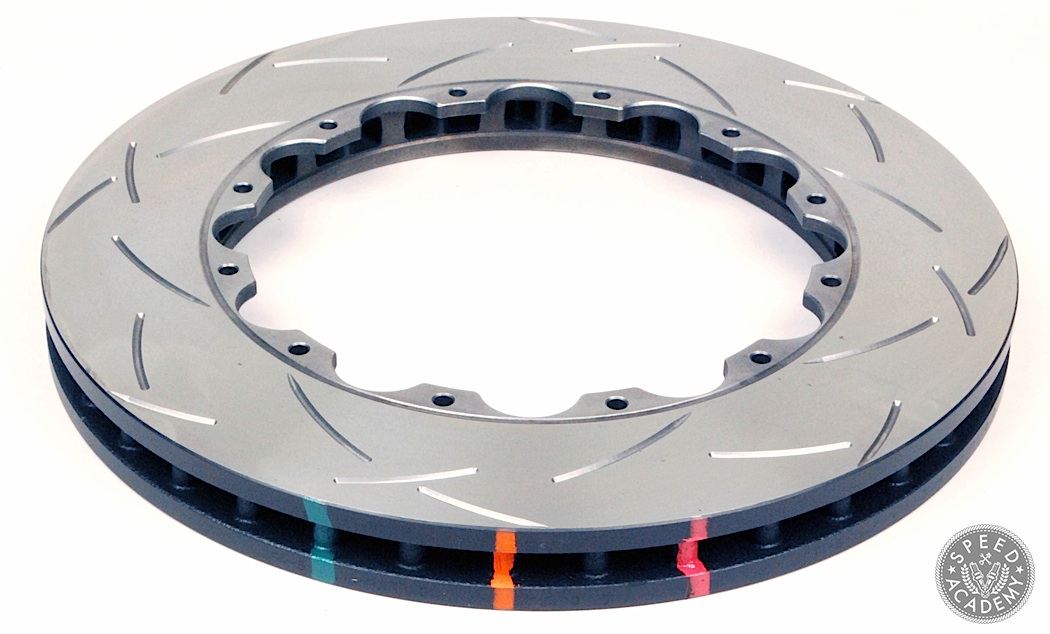

DBA T3 5000 Series slotted rotor ring, with thermographic paint to allow you to easily see how hot your rotors are getting on the street or at the track

A slotted disc face is also designed to refresh the pad surface, which helps maintain more consistent frictional performance. The frequency and shape of these slots depends on a number of design considerations including how much initial bite and torque the engineers are looking to generate. As Yoni from DBA explained, “We developed the T3 slot design that has its own inherent advantages over a straight slot, such as increased pad life and reduced noise. And for any motorsport application, we suggest using a slotted-only rotor. We do offer our XS drilled and slotted design as well, but this is aimed more at the street applications, where the drilled look is preferred, but the performance is also important. So we designed a pattern that offers both drilling and small slots to obtain the best of both worlds. Typically, these are used in situations where the rotors won’t be subjected to the long term heating and cooling that is common in racing.”

Material type and quality is also critically important to rotor performance. The most affordable and commonly used material for brake discs is cast iron, but not all cast iron is created equal. Companies like Brembo and DBA have spent years, decades even, perfecting their cast iron formulations for maximum durability and performance. As Mark from Brembo pointed out, “There are near limitless potential alloys when formulated a cast iron brake disc. Brembo is unique in that we have our own foundries and control the product from raw material through to final product. We develop our own proprietary alloys for use in our brake discs. The material and casting process itself affect the friction coefficient of the disc, wear rate, strength, resistance to thermal shock and thermal fatigue, resistance to corrosion, and much more.”

Yoni from DBA had this to add on the subject of material quality: “There are a lot of factors that contribute to a poor quality rotor, internal vaning, air gap, tolerances, etc., but material composition and overall quality control really shows up when the rotors are used in a performance application. DBA does have our main foundry in Australia, as well as other facilities located around the world. We do have a specific formulation we use, which requires a certain level of carbon in the rotors. While this sounds really easy, just toss more carbon into the rotor, right? It’s actually much more complicated than that, which is why you don’t see the levels of carbon we use in our rotors elsewhere. The best example I can use is this: think about adding sugar to your coffee. Putting a little bit in is fine and it dissolves quickly, but as you continue to add more sugar, you have to work harder to dissolve the sugar. Most rotors are made at the ‘easy to dissolve’ levels. We add more which requires special techniques that we implement to ensure our rotors can hold up to the abuse.”

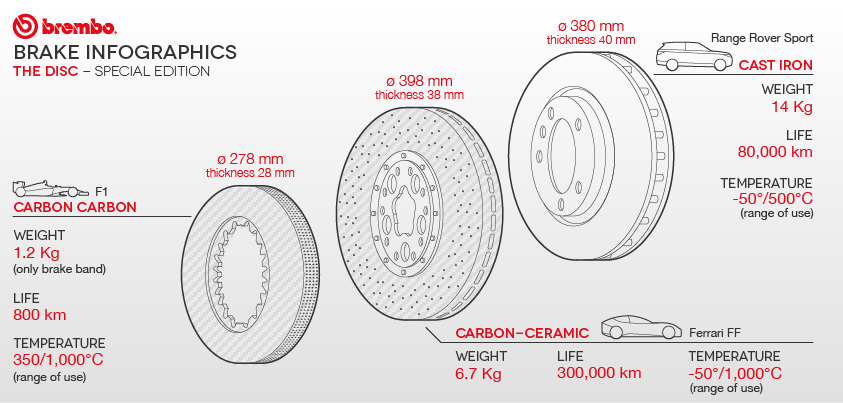

Speaking of carbon, as I mentioned at the top, carbon ceramic and full carbon disc brakes are also available, with significant advantages and disadvantages associated with them. As Mark from Brembo explained, “Carbon-based brake discs still must perform the same function as their cast iron counterparts. The advantages they possess are related to their temperature resistance and weight. The maximum temperature of a carbon-based brake disc is much higher than that of cast iron. Carbon-carbon racing discs are also coupled with carbon-carbon pads, resulting in a brake system that is very much different than those with cast iron discs. However, with road-going carbon-ceramic systems, the brake pad material is very much like that used for cast iron discs, so the characteristics are more comparable.”

The biggest downside to carbon ceramic discs is cost. In a racing environment they wear at a similar rate to a cast iron rotor (though will last much, much longer during normal street use, as the above infographic from Brembo highlights) and cost more than most of the project cars in our fleet. Need a new set of carbon ceramic rotors for your 997 GT3? No problem, that’ll be $9400 for the front pair and $8500 for the rear pair. With that harsh realization in mind, I think it’s fair to say that carbon ceramics are really only a good choice for track day enthusiasts with big budgets who greatly value the 50% weight savings over a cast iron equivalent.

The other downside to carbon ceramic rotors is some loss of pedal feel or initial bite at light pedal pressures. Drivers new to carbon ceramic rotors are often thrown off by the squishy feeling of the brake pedal, a result of this material needing a fair bit of heat in it before it starts to provide a similar pedal feel to a cast iron rotor. Having track testing quite a few cars with carbon ceramic rotors, I can tell you they feel completely normal in this environment because there’s no shortage of heat out on the track, but on the street that squishy or soft feel they have when you first start applying the brakes can be a bit disconcerting.

We retrofitted some Evo calipers and stepped up to DBA’s 5000 series two-piece rotors on the front of our S14, a budget conscious package that delivers fade-free performance at the race track.

So for us regular folk, a high quality cast iron rotor is almost certainly the solution for our track day needs, and with the information outlined above you should be better equipped to decide if your car will benefit from a two-piece setup or can get by with a high quality one-piece design. Taking some rotor temps with a pyrometer is a great way to get a sense of the workload your rotors are being asked to do, so get out there, collect some data, and then choose a rotor setup that’ll get the job done as efficiently and as cost-effectively as possible, keeping in mind of course that with disc brakes (like most things in life) you do get what you pay for. So don’t cheap out and order some eBay specials if you plan to hit the track — for that you’ll need to man up and buy some high-performance rotors designed for these high stress conditions. Some cars, like my G35, benefit tremendously from a big brake kit, while others, like our S2000, really only needs a basic rotor, pad and fluid upgrade to be fully track ready.

I’ve been needing to get some new disc brakes for my wife’s car. I’m glad you talked about different rotor designs for disc brakes, which I think is interesting. I’m going to have to look into a few god disc brake services and see what we can get!