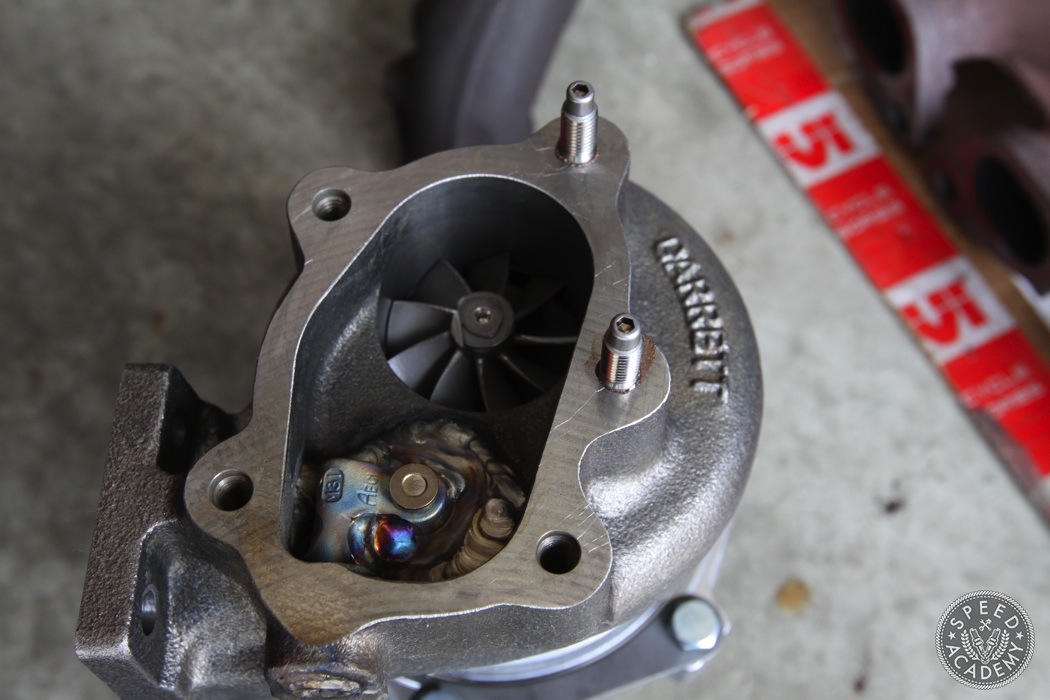

The next item on the to do list was to weld up the internal wastegate flapper on the exhaust housing. The only real drawback to running an upgraded stock housing turbo is they tend to boost creep. The solution is to go with an external wastegate setup.

As I mentioned before, I wanted to retain the stock heat shielding and manifold so that meant fabricating a flange for the external gate. I left this up to my friends over at Centerline Motorsports.

They had the proper equipment to do the job but if you’ve got the time and willingness to cut a large hole with hand tools at home I don’t doubt it can be done.

There’s also an exhaust divider on the outlet side of the manifold that has to be cut out so don’t forget that.

The next order of business was to figure out how to dump the wastegate back into the exhaust tract. No screamer pipes for me, I have too much respect for the environment.

Using Vibrant‘s extensive catalogue of fabrication parts, I sourced 1.5-inch stainless steel piping and a bellows assembly (that accordion looking pipe) since it handles vibration and heat expansion in the piping. Without stress cracks can happen quite frequently.

A hole matching the wastegate dump piping was cut into the Tomei O2 housing.

Top Writeup. Badass Job.

Curious, why didn’t you purchase the turbo with a turbine housing made for an external wastegate? (instead of welding up the internal wastegate and modding the stock manifold and all that)

Great write, thank you for taking the time!

Which bov are you using?

Does this setup utilize the stock bov plumb back?