What’s the latest buzz in the racing community? “It’s got the shifting speed of a sequential, with the maintenance and reliability of an OEM gearbox.” That’s right, we are talking about DCT or dual-clutch transmissions! I’ll shed some light on what the heck they even are, pros, cons, and some of the parts you’ll need to put one in your race car.

What is a DCT?

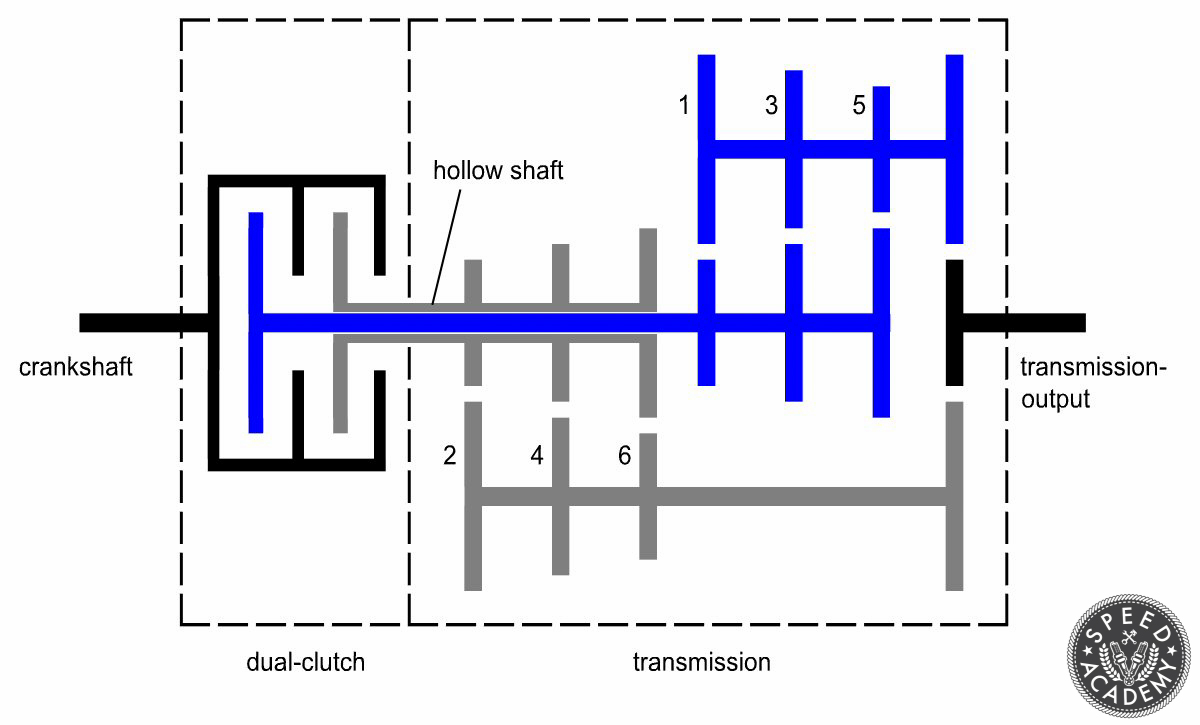

Let’s break down what a DCT is in the simplest way. Imagine you have two transmissions with two separate clutches. One transmission and clutch control the even numbered gears and the other controls the odd numbered gears. There are two input shafts, with one fitting inside the other. The shifts are all electronically controlled and do not require input from the driver, but can be actuated with paddles or a lever. The clutch packs are internal, instead of being external like in a manual transmission and are either ‘wet’ or ‘dry.’ Enthusiasts would be most interested in ‘wet’ gearboxes, as the clutch packs are bathed in oil to cool them down. What that means for you and me is that it enables the clutch packs to handle more torque. If that’s not enough for you though, Exedy does sell upgraded clutch packs.

Pros

There are quite a few pros to a DCT compared to a traditional manual transmission. The first one is obvious: speed. Some DCTs can shift a gear in just 40 milliseconds compared to the 500 milliseconds that a typical human takes while driving in anger. This is a big deal when it comes to cars that are turbocharged. It cuts down the time that the turbo doesn’t receive exhaust gas flow, which, in layman terms, helps the engine remain in boost. A ‘true sequential’ can be even faster, but a motorsports gearbox has a lot of negatives: cost, maintenance, and availability just to name a few.

Another key element is the elimination of the clutch pedal. I know some of you ‘purists’ just threw your phone out the window because you would be losing the “driving experience,” and if that’s the case then this may not be the transmission for you. When you are on track, though, not having to worry about downshifting and heel-toeing is a huge advantage no matter how good you are at rev matching. Imagine being able to left foot brake every corner; the amount of time you can shave adds up fast.

Lastly, these gearboxes can be found in road going cars such as the E90/92 BMW 335 and M3, which means they have gone through a ton of engineering to make sure they operate correctly. The amount of research and development that goes into an OE manufactured part is truly amazing. DCT’s also have an advantage over a motorsports sequential gearbox in a key way; you don’t need to install a hydraulic or pneumatic system if you want to run paddles for shifting since it’s all integrated into the transmission.

Cons

It isn’t all rainbows and unicorn farts though, there are some cons to these types of swaps. One of them is weight. For example, the GS7D36SG gearbox out of an E92 BMW weighs around 150-lbs. In comparison, an S2000 transmission weighs roughly 50-lbs less. Imagine trying to replace your transmission at the track while you are laying on your back, debating what made you make these poor choices in the first place.

That leads me to my next con; the DCT gearbox is massive. It’s far wider than most transmissions, so it will need some editing to get in. Yes, editing means cutting up your car or getting my favorite tool, a big freaking hammer and bashing some sheet metal. The other big hurdle is controlling the DCT. Earlier, we talked about how the gearbox is controlled electronically. Well if you are familiar with BMWs, you know their electronics can be rather complicated. The BMW system uses a transmission control unit (TCU). This can be rather difficult and time consuming to get into your project car but I’ll go into details on some solutions later on.

Transmission Options & My Choice

With all those cons being said, I’m still putting one in my S2000. The benefits are worth the extra complexity for me. If you’d like to do the same, the first thing you’ll need to do is figure out what transmission you want. The go-to option for front engined, rear wheel drive platforms is the GS7D36SG. These can be found in a plethora of BMW chassis. There are different variants, two have bell housings for the inline 6’s and the others for the V8s. The V8 version typically holds more torque since they were made for the M series vehicles. The trade-off is the bell housing is also bigger, but if you are mating one to a bigger engine, such as an LS series engine, it may be the right one for you. I ended up with the 6 cylinder version out of an ’08 335i. At the time that I started this project, this transmission was dirt cheap, $450 USD to be exact.

Adapters & Adapter Plate

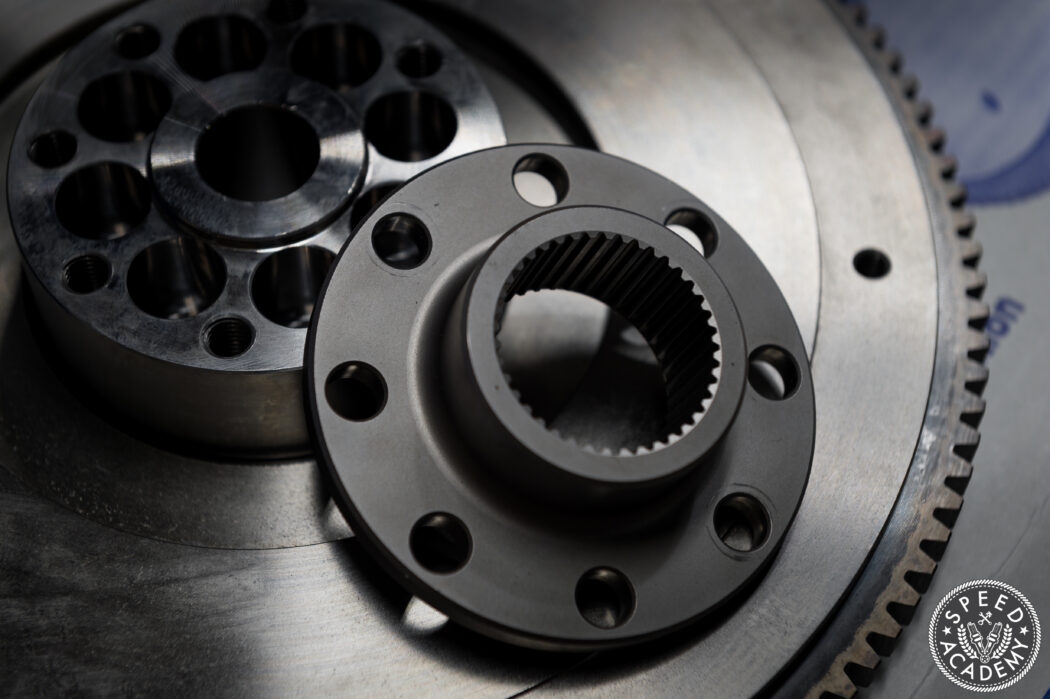

Simply put, you need one! I’m going to use Domiworks for this task. I love the way they engineer their plates and the fact that it comes with all the bolts and detailed instructions. Other companies make them for different engine configurations as well. A simple Google search on your engine should turn up some choices for all the popular engines such as LSx, K Series, SR, RB, JZ, you get the point. You will also need an OE flywheel (such as this Exedy K24 flywheel) for some kits. For example, the Domiworks K20/24 adapter kit has a two-piece hub that you bolt onto an OE-style flywheel. Some other kits supply a flywheel with the hub for the DCT integrated into it.

Drivetrain Notes

Currently, there aren’t many off-the-shelf options for driveshafts and transmission mounts. You’ll have to have them both fabricated. Drag racing and street rod guys have been doing things like this for years. There are plenty of websites and local companies that will make a driveshaft for you if you know the length from the transmission to the rear differential and what flanges are on both sides. That’s also where products like the Domiworks 1350 yoke pattern can save you some money. It’s a much more common flange than the one that comes on most DCTs.

You will also need a parking unlock mechanism that looks like this. None of the transmission management systems currently control the parking mechanism, so the easy thing to do is simply delete it.

Transmission mounting may be a little more tricky than usual, but any decent fabricator should be able to make one for whatever chassis and engine and transmission configuration you you’re working with. As of right now, the only off-the-shelf transmission mounts I could find are for older BMW E36s from Seems Legit Garage. I’m sure there are more out there but since I can’t find one for my S2000, I’m angrily leaving that search for you.

Trans Controller/Electronics

The biggest hurdle with these gearboxes is the electronics. As I stated above, these are controlled by a transmission control unit that is tied into the BMW electrical system. To my knowledge, there are two main options for budget-minded individuals like you and me. One option is the Maxx ECU and the other is the HTG Tuning GCU (Gearbox Control Unit). I personally will be using HTG since it seems to have an endless amount of tunability to it. However, as the saying goes “With great power comes great responsibility”, so as you might expect the HTG requires a lot of time to configure all the different parameters to control the transmission. That said, groups like the HTG Tuning Community are a lot of help. Even with great support, it’s important to understand that it will still take many hours to get this gearbox operating in an efficient manner.

That’s not all you need, either. A modified printed circuit board (PCB) has to be installed inside the transmission which requires some soldering. You will also need to wire in an external harness that connects to the GCU. But wait, there’s more! You also need to wire a harness inside the gearbox to the Mechatronics unit in the trans! Last but not least, be sure to mount the GCU in a safe location!

Cooling System

You will also need to find a place to mount a cooler. Since these gearboxes have their clutch packs in oil, they will need a standalone cooler. Better yet, treat it like your engine oil. Find a nice place to mount it where it gets some air. Grab an oil cooler adapter from Domiworks, run some lines and be done. I will reiterate, treat it like your engine oil, don’t put the cooler on top of your turbo and wonder why your trans exploded. You’ve been warned! It’s also worth noting that the oil pans on these gearboxes have been reported to be very fragile. There are some nice billet units on the market but when you read the word billet you should already know what the price point is.

What Next?

The performance ceiling for these boxes is so high and once things become more plug and play, oh my. The lap times at Gingerman Raceway (the only track that matters in North America, according to me) are already dropping at an alarming rate. What if everyone had the shifting speed of the new Supra without the weight penalty? Oh freaking boy, that’s exciting! The car known as Super K linked above is proving that it’s not close to a plug and play task just yet, but the future looks bright. I’ll check back with you on what’s going on with mine.

Instagram: Proawesomedevin

Podcast: HyperCritical Presented by Professional Awesome

Facebook Discussion Group: Professional Awesome Support Group

The Best Speed Academy articles: Speed Academy – Devin Giles